Imikhiqizo

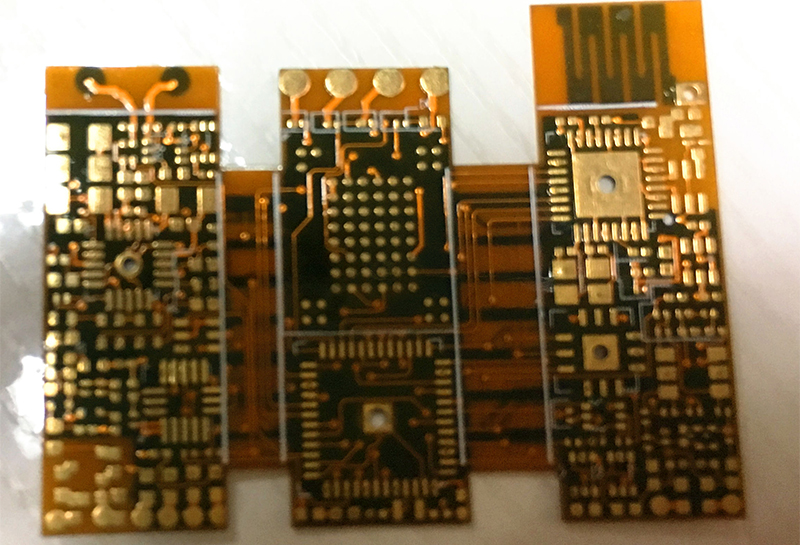

4 ungqimba FPC nge-FR4 Stiffener ku-4G Module System

| Izebele | Izingqimba ezi-4 ziguquguqukayo |

| Ukuqina kwebhodi | 0.2mm |

| Into uqobo lwayo | I-polymmide |

| Ubukhulu bethusi | 1 oz (35um) |

| Qeda phezulu | Ubukhulu be-enig au 1um; NI ubukhulu 3um |

| Min Hole (MM) | 0.23mm |

| Ububanzi bemigqa yeminithi (mm) | 0.15mm |

| Isikhala se-Min Line (MM) | 0.15mm |

| Imaski yomthengisi | -Yimpatho |

| Umbala we-legend | Okumhlophe |

| Ukucutshungulwa kwemishini | I-V-CORES, CNC Milling (Umzila) |

| Ukufaka ndawonye | Isikhwama se-Anti-Static |

| Ukuhlola | Ukundiza kwendiza noma ukuhlanganiswa |

| Ukwamukelwa okujwayelekile | I-IPC-A-600H CLASS 2 |

| Isicelo | Izithuthi Zokwe-Electronive |

Ukuqalisa

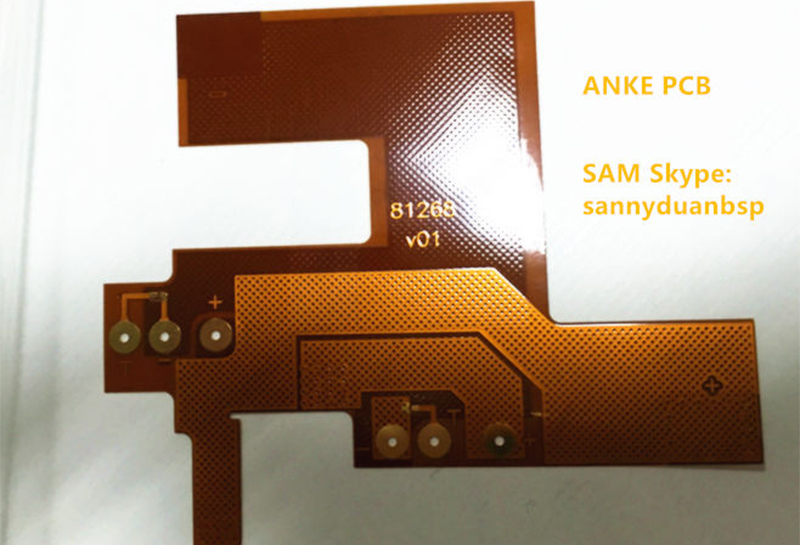

I-PCB eguquguqukayo iyindlela ehlukile ye-PCB ongayigoba ibe ngumomo oyifunayo. Ngokuvamile asetshenziselwa ubungako obuphezulu kanye nokusebenza okuphezulu kokushisa.

Ngenxa yokumelana kwayo okuhle kakhulu, umklamo oguquguqukayo ulungele izingxenye zokubeka eceleni. Ifilimu ebonakalayo ye-polyester esetshenziselwa ukwakha imiklamo eguqukayo isebenza njengezinto ezingaphansi komhlaba.

Ungaguqula ubukhulu be-Copper ungqimba kusuka ku-0.0001 "kuya ku-0.010", ngenkathi impahla ye-dielectric ingaba phakathi kuka-0.0005 "no-0.010" obukhulu. Njalo ukuxhumanisa ekwakhiweni okuguquguqukayo.

Ngakho-ke, kukhona ukuxhumana okumbalwa okuthengiswayo. Ngokwengeziwe, le mibukela ithatha ama-10% we-10% yendawo eqinile yebhodi

ngenxa yokugunda kwabo okuguquguqukayo.

Into uqobo lwayo

Izinto eziguquguqukayo neziguquguqukayo zisetshenziselwa ukukhiqiza ama-PCB aguqukayo. Ukuguquguquka kwayo kuvumela ukuthi kuguqulwe noma kuhanjiswe ngaphandle komonakalo ongaphenduki ezingxenyeni zawo noma ukuxhumana.

Yonke ingxenye ye-PCB eguqukayo kufanele isebenze ngokubambisana ukuze isebenze. Uzodinga izinto ezahlukahlukene zokuhlanganisa ibhodi eliguqukayo.

Mboza ungqimba substrate

Isithwali somqhube kanye nokufaka okuphakathi kokuthola umsebenzi we-substrate nefilimu. Ngokwengeziwe, i-substrate kumele ikwazi ukugoba futhi i-curl.

Amashidi e-polymide ne-polyester ajwayele ukusetshenziswa emibuthanweni eguqukayo. Lawa angamafilimu ambalwa nje ama-polymer ongawathola, kepha kuningi ongakhetha kuzo.

Kuyindlela engcono ngenxa yezindleko eziphansi kanye nekhwalithi ephezulu yekhwalithi ephezulu.

I-PI polyimide iyinto esetshenziswa kakhulu ngabakhiqizi. Lolu hlobo lwe-thermostatic resin lungamelana namazinga okushisa aphezulu. Ukuncibilika akulona inkinga. Ngemuva kwe-polymerization eshisayo, isagcina ukuqina kwayo nokuvumelana nezimo. Ngaphezu kwalokhu, inezindawo ezinhle kakhulu zikagesi.

Izinsiza zomqhubi

Kufanele ukhethe into yomfundo edlulisela amandla kahle kakhulu. Cishe yonke imibuthano yobufakazi bobufakazi basebenzisa ithusi njengomqhubi wesifundo sokuqala.

Ngaphandle kokuba ngumshayeli omuhle kakhulu, ithusi futhi kulula ukulithola. Uma kuqhathaniswa nentengo yezinye izinto zomqhubi wesifundo, ithusi liyingxoxo. Ukuvuselelwa akwanele ukuqeda ukushisa ngempumelelo; Kufanele futhi kube ngumqhubi omuhle we-thermal. Imibuthano eguquguqukayo ingenziwa kusetshenziswa izinto zokwakha ezinciphisa ukushisa ezikhiqizayo.

Adhesives

Kukhona ukunamathela phakathi kweshidi le-polymide kanye nethusi kunoma iyiphi ibhodi yesekethe eliguqukayo. I-epoxy ne-acrylic kuyizindawo ezimbili eziphambili ongazisebenzisa.

Ama-adhesives aqinile adingekayo ukuphatha amazinga okushisa aphezulu akhiqizwa yi-zethusi.