Ngokushintsha okusheshayo kwempilo yamanje yesimanje okudinga izinqubo ezengeziwe ezengeziwe ezithuthukisa ukusebenza kwamabhodi esifunda sakho ngokuphathelene nokusetshenziswa kwawo okuhlosiwe, noma zisize ngezinqubo zokuhlanganisa izigaba eziningi ukuze kuncishiswe abasebenzi futhi kuthuthukiswe ukusebenza kahle kokusebenza, i-ANKE PCB iyanikezela. ukuthuthukisa ubuchwepheshe obusha ukuze buhlangabezane nezidingo zamakhasimende ngokuqhubekayo.

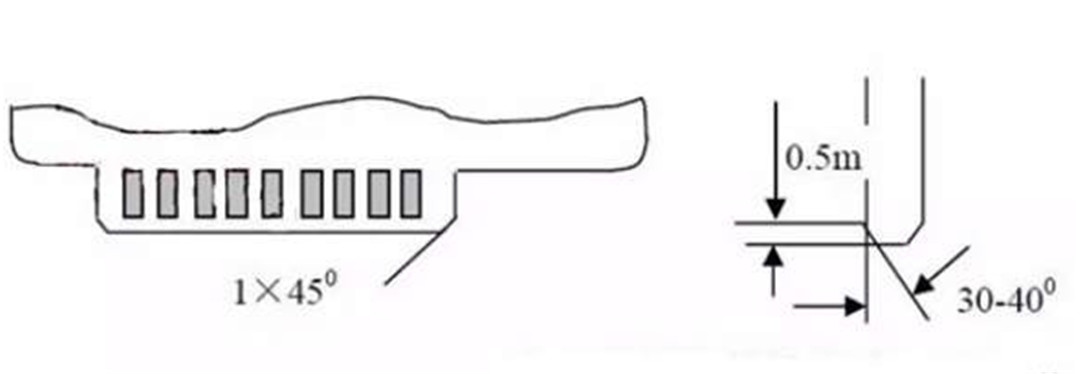

Isixhumi somphetho sikhala ngomunwe wegolide

Isixhumi se-Edge bevelling ngokuvamile sisetshenziswa eminwe yegolide kumabhodi anegolide noma amabhodi e-ENIG, ukusika noma ukulolongwa kwesixhumi esinqenqemeni nge-engeli ethile.Noma yiziphi izixhumi ezinama-beveled PCI noma ezinye zenza kube lula ukuthi ibhodi lingene kusixhumi.I-Edge Connector bevelling iyipharamitha emininingwaneni ye-oda okudingeka uyikhethe futhi uhlole le nketho lapho idingeka.

Ukuphrinta kwekhabhoni

I-Carbon print yenziwe nge-ink ye-carbon futhi ingasetshenziselwa othintana nabo bekhibhodi, abathintwayo be-LCD kanye nama-jumpers.Ukuphrinta kwenziwa ngeyinki ye-carbon conductive.

Ama-elementi ekhabhoni kumele amelane nokusoda noma i-HAL.

I-insulation noma ububanzi be-Carbon akumele behlise ngaphansi kuka-75 % yenani elivamile.

Kwesinye isikhathi i-mask exegayo iyadingeka ukuze uvikele ekugubheni okusetshenzisiwe.

I-soldermask ecwecwe

I-soldermask ecwecwayo Isendlalelo sokumelana ne-peelable sisetshenziselwa ukumboza izindawo okungafanele zithengiswe ngesikhathi senqubo ye-solder wave.Lesi sendlalelo esiguquguqukayo singabe sesisuswa kalula ukuze kushiywe amaphedi, izimbobo nezindawo ezidayiswayo ezisesimweni esikahle sezinqubo zokuhlangana kwesibili kanye nokufakwa kwengxenye/isixhumi.

Ama-vais ayizimpumputhe futhi angcwatshwe

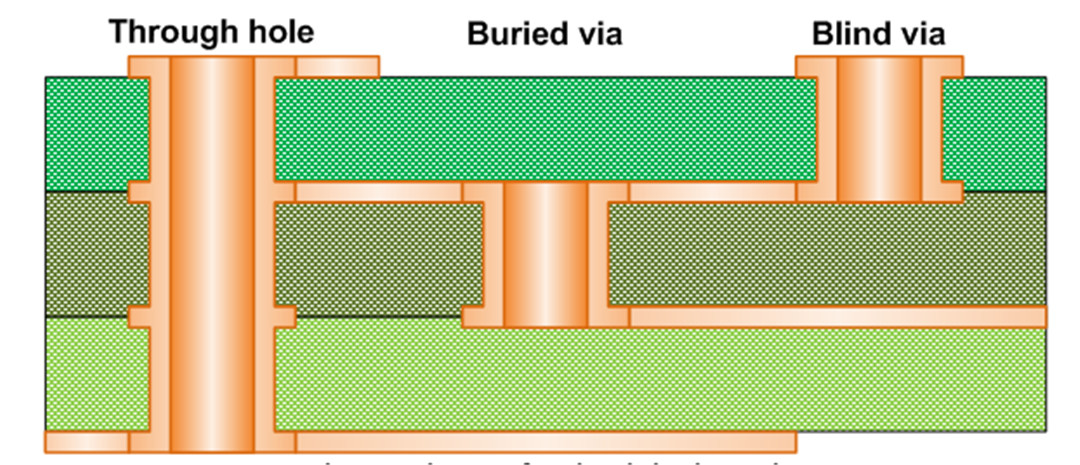

Iyini i-Blind Via?

Uma ungaboni ngaso linye, i-via ixhuma isendlalelo sangaphandle kwesendlalelo esisodwa noma eziningi zangaphakathi ze-PCB futhi inesibopho sokuhlangana phakathi kwalolo ngqimba olungaphezulu nezindlalelo zangaphakathi.

Kuyini Ukungcwatshwa Nge?

Endleleni engcwatshwe, yizingqimba zangaphakathi kuphela zebhodi ezixhunywe nge-via."Ingcwatshwa" ngaphakathi kwebhodi futhi ayibonakali ngaphandle.

Ama-vias angaboni noma angcwatshwe azuzisa kakhulu kumabhodi e-HDI ngoba akhulisa ukuminyana kwebhodi ngaphandle kokukhuphula usayizi webhodi noma inani lezendlalelo zamabhodi ezidingekayo.

Indlela yokwenza i-vias eyimpumputhe&engcwatshwe

Ngokuvamile Asisebenzisi ukubhola kwe-laser okulawulwa ukujula ukuze sikhiqize izimbotshana ezingaboni kanye nezigqitshiwe.Okokuqala sibhoboza i-cores eyodwa noma ngaphezulu bese sipuleka emigodini.Bese sakha futhi sicindezela isitaki.Le nqubo ingaphinda izikhathi eziningana.

Lokhu kusho:

1. I-A Via njalo kufanele inqamule inani elilinganayo lezingqimba zethusi.

2. I-Via ayikwazi ukuphelela ohlangothini olungaphezulu lwengqikithi

3. I-Via ayikwazi ukuqala ohlangothini olungezansi lwe-core

4. Indlela Eyimpumputhe noma Engcwatshwayo ayikwazi ukuqala noma iphele ngaphakathi noma ekupheleni kwenye Impumputhe/Engcwatshwe ngaphandle uma ivalelwe ngokuphelele kwenye (lokhu kuzokwengeza izindleko ezengeziwe njengoba kudingeka umjikelezo wokushicilela owengeziwe).

Ukulawulwa kwe-impedance

Ukulawulwa kwe-Impedans bekungenye yezinto ezikhathazayo ezibalulekile nezinkinga ezinzima ekwakhiweni kwe-pcb ngesivinini esikhulu.

Kuzinhlelo zokusebenza zemvamisa ephezulu, i-impedance elawulwayo isisiza ukuthi siqinisekise ukuthi amasiginali azonakaliswa njengoba ezungeza i-PCB.

Ukumelana nokusabela kwesekethe kagesi kunomthelela omkhulu ekusebenzeni, njengoba izinqubo ezithile kufanele ziqedwe ngaphambi kwabanye ukuze kuqinisekiswe ukusebenza okufanele.

Empeleni, i-impedance elawulwayo iwukufaniswa kwezinto ezibonakalayo ze-substrate ezinobukhulu bokulandelela kanye nezindawo ukuze kuqinisekiswe ukuthi ukuphazamiseka kwesiginali ye-trace kungaphakathi kwephesenti elithile yenani elithile.