Imikhiqizo

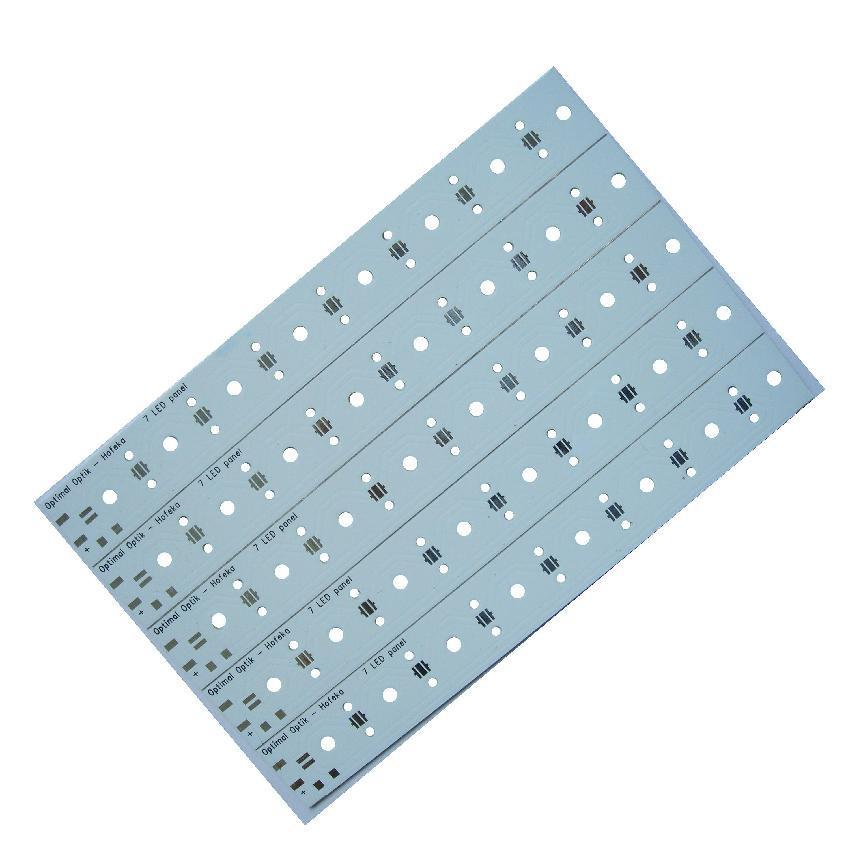

I-Aluminium Led Tube Light PCB

Imininingwane Yomkhiqizo

| Izebele | 1 izingqimba |

| Ukuqina kwebhodi | I-1.6mm |

| Into uqobo lwayo | Isisekelo se-Aluminium |

| Ubukhulu bethusi | 1 oz (35um) |

| Qeda phezulu | Lf hasl |

| Min Hole (MM) | 0.3mm |

| Ububanzi bemigqa yeminithi (mm) | 0.25mm |

| Isikhala se-Min Line (MM) | 0.25mm |

| Imaski yomthengisi | Okumhlophe |

| Umbala we-legend | -Mnyama |

| Ukucutshungulwa kwemishini | I-V-CORES, CNC Milling (Umzila) |

| Ukufaka ndawonye | Isikhwama se-Anti-Static |

| Ukuhlola | Ukundiza kwendiza noma ukuhlanganiswa |

| Ukwamukelwa okujwayelekile | I-IPC-A-600H CLASS 2 |

| Isicelo | Izithuthi Zokwe-Electronive |

I-Metal Core PCB noma i-MCPCB

I-Metal Core PCB (MCPCB) yaziwa njenge-PCB ye-PCB ye-Metal Backplane noma i-PCB ye-Thermal. Lolu hlobo lwe-PCB lusebenzisa impahla yensimbi esikhundleni se-fr4 ejwayelekile yesisekelo sayo, ingxenye yokushisa yokushisa yeBhodi.

Njengoba kukhiqizwa ukushisa okwaziwayo kukhiqizwa ebhodini ukuthola izizathu ezithile ze-elekthronikhi ngesikhathi sokusebenza. I-Metal Transfers Ukushisa Kusuka ebhodini lesekethe futhi uphinde uqondise kabusha ku-Metal Core noma ngensimbi Heat Heat Snging Base Ukuxhaswa kabusha kanye nento ebalulekile yokonga.

Ku-PCB ye-Multilayer uzothola inombolo efanayo yezingqimba ezisatshalaliswa ohlangothini lwensimbi. Isibonelo, uma ubheka kwi-PCB enobungqingili, uzothola izingqimba eziyisithupha ngaphezulu nangezingqimba eziyisithupha ezansi, phakathi, phakathi yimongo yensimbi.

I-MCPCB noma i-Metal Core PCB eyaziwa nangokuthi i-ICPB noma i-PCB yensimbi yensimbi, i-IMS noma i-Insured Metal Substrates, i-PCBS yensimbi ye-Clad kanye ne-PCB ye-Clad ne-Thermal Clad PCB.

Ngawe ukuqonda okungcono sizosebenzisa nje igama le-PCB ye-Metal Core kuyo yonke le ndatshana.

Ukwakheka okuyisisekelo kwe-PCB yensimbi eyi-Core Core kufaka okulandelayo:

Ungqimba lweCopper - 1oz.to 6oz. (okuvame kakhulu yi-1oz noma 2oz)

ungqimba wesifunda

Ungqimba lwe-dielectric

Imaski yomthengisi

Isinki sokushisa noma isinki sokushisa (ungqimba lwensimbi oluyisisekelo)

Inzuzo ye-MCPCB

Ukuvuselelwa okushisayo

I-CEM3 noma i-FR4 ayilungile ekwenzeni ukushisa. Uma kushisa

Ama-substrates asetshenziswa kuma-PCB anokuphakelayo okungalungile futhi angalimaza izingxenye zebhodi le-PCB. Yilapho ama-PCB e-Metal Core Core esebenza.

I-MCPCB inokuvuka okuhle kakhulu okushisayo ukuvikela izingxenye ngomonakalo.

Ukuvimbela Ukushisa

Inikeza umthamo omuhle kakhulu wokupholisa. I-Metal Core PCBS ingahlukanisa ukushisa kusuka ku-IC kahle kakhulu. Ungqimba olusenzile olushwabene bese ludlulisela ukushisa ku-substrate yensimbi.

Ukuqina kwesikali

Inikeza ukuqina okuphezulu kobukhulu kunezinye izinhlobo zama-PCB. Ngemuva kokuthi izinga lokushisa liguqulwe lisuka ku-30 degrees Celsius libe ngu-140-50 degrees Celsius, ukuguqulwa okuyisici kwe-aluminium metal core ngu-2,5 ~ 3%.

Yehlisa ukuhlanekezela

Njengoba ama-PCB e-Metal Core CORE anokuhlanza okushisa okuhle nokuvuselelwa okushisayo, athambekele kangako ekuguqukeni ngenxa yokushisa okubandayo. Ngenxa yalesi simo se-Metal Core, ama-PCB kuyindlela yokuqala yokuthola ama-Power Supply adinga ukushintshwa okuphezulu.