Okokusebenza komhlangano we-PCB

I-ANKE PCB inikezela ngocingo olukhulu lwemishini ye-SMT kubandakanya amabhukwana, ama-stencil ama-stencil azenzakalelayo futhi azenzakalelayo azenzakalelayo, i-Pick & Pet Machines kanye ne-batch ye-benchtop kanye nevolumu ephakathi nendawo ephansi

E-Acke PCB Siyiqonda ngokuphelele ikhwalithi iyinhloso eyinhloko yomhlangano we-PCB futhi okwazi ukufeza indawo yombuso-we-art-of-art ehambisana nokufakwa kwe-PCB kwakamuva kwe-PCB kanye nemihlangano.

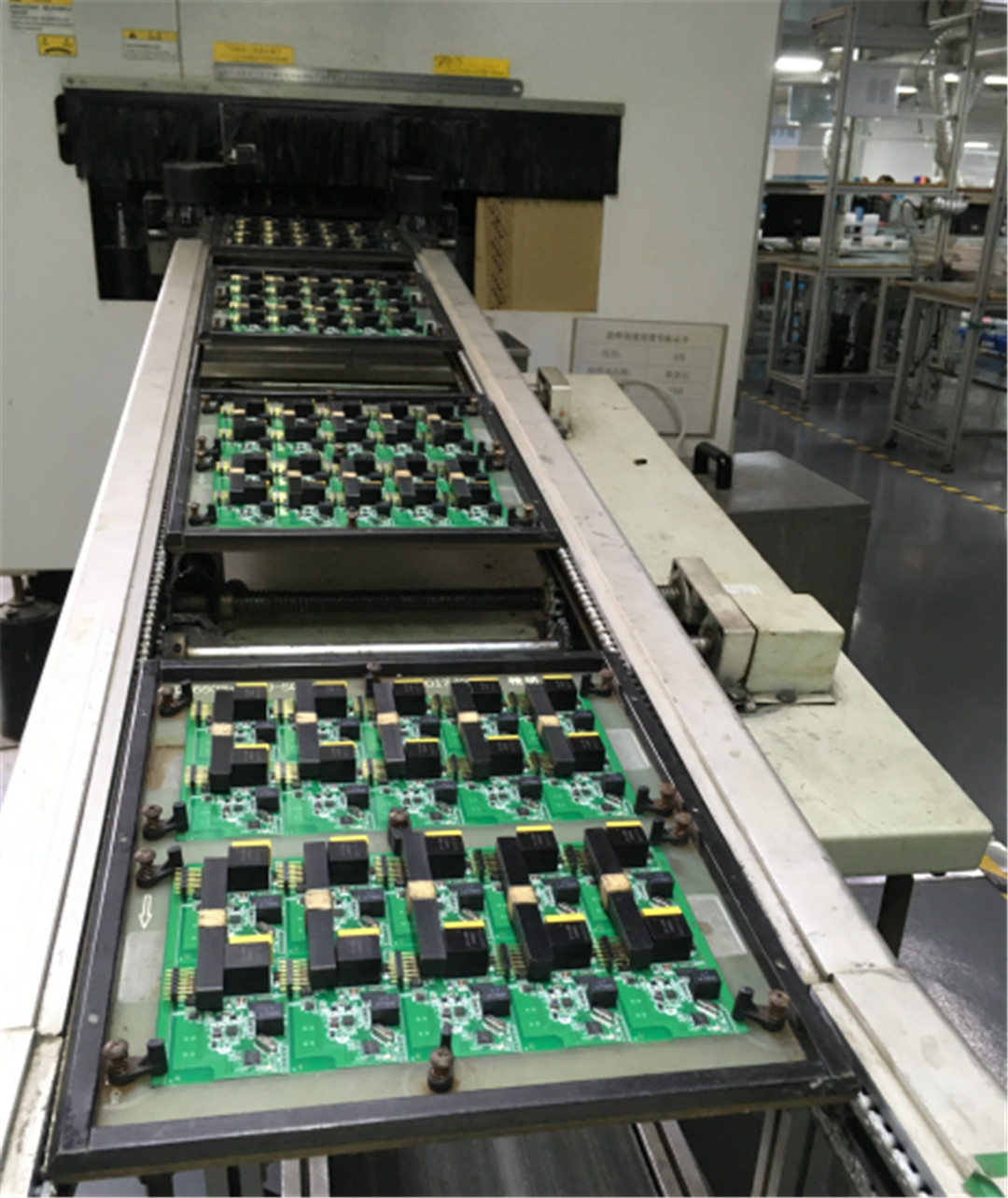

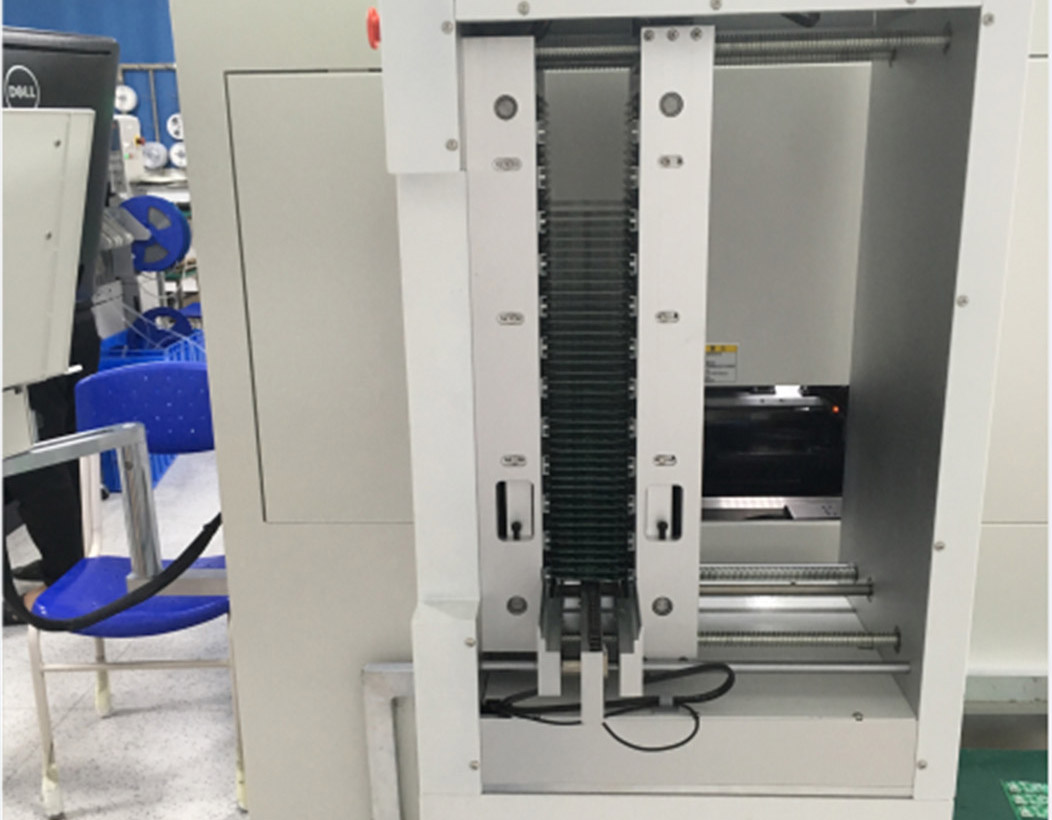

I-PCB Outomatic

Lo mshini uvumela amabhodi we-PCB ukondla umshini wokuphrinta othomathikhi wokunamathisela okuzenzakalelayo.

Imbuyiselo

• Ukulondolozwa kwesikhathi kwabasebenzi

• Ukulondolozwa kwezindleko ekukhiqizeni umhlangano

• Ukunciphisa iphutha okungenzeka okuzobangelwa yincwajana

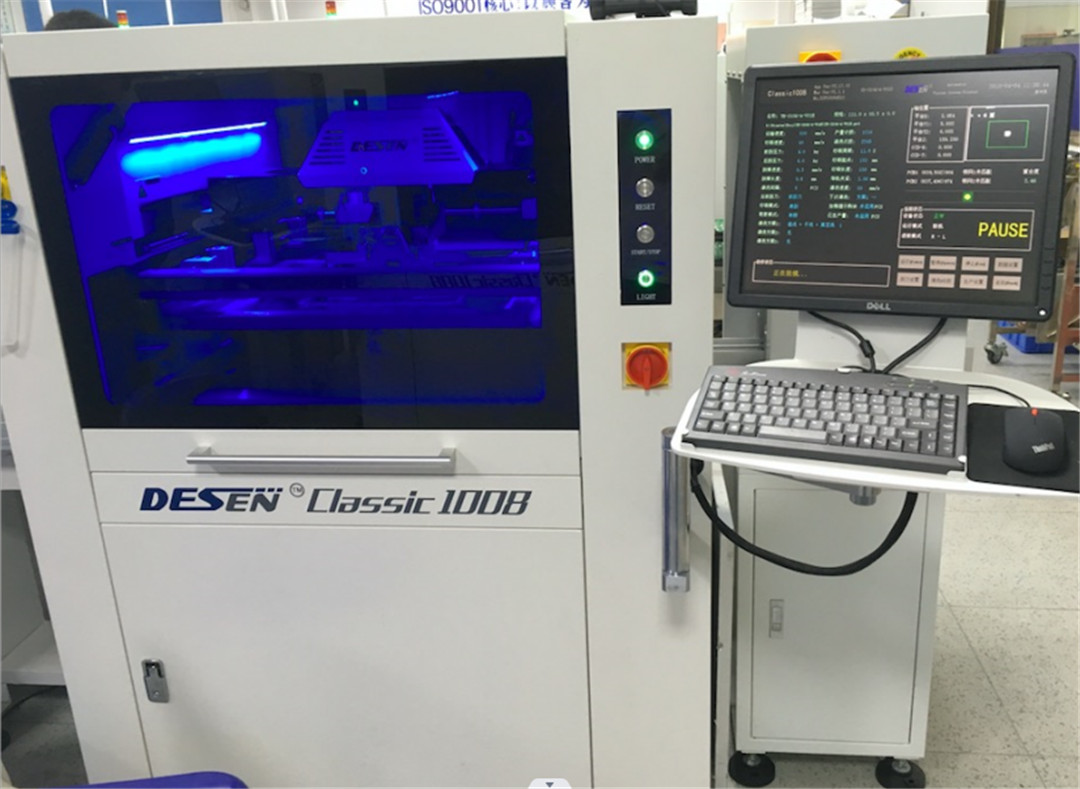

Iphrinta ye-automatic stencil

I-ANKE inezinkomba ze-Advenul zifana nemishini yokuphrinta ye-automatic stencil.

• Ukuhlelwa

• Uhlelo lwe-squeegee

• I-Stencil Automatic Simo System

• Uhlelo lokuhlanza oluzimele

• Uhlelo lokudluliselwa kwe-PCB kanye nesikhundla

• Isibonisi esisebenziseka kalula esiNgisi / isiShayina

• Uhlelo lokuthwebula izithombe

• Ukuhlolwa kwe-2D & SPC

• I-CCD Stencil ukuqondanisa

I-SMT PICK & SDICAD SDINES

• ukunemba okuphezulu nokuguquguquka okuphezulu kwe-01005, 0201, i-SAIC, PLCC, BGA, MBGA, CSP, QFP, kuze kube yi-Fine-Pitch 0.3mm

• Uhlelo lokungathintwanga lwe-Encoder liqondile lokuphindaphinda okuphezulu nokuqina

• Uhlelo lwe-Smart Loeder lunikeza ukuhlolwa kwesikhundla okuzenzakalelayo, ukubalwa kwengxenye ezenzakalelayo, ukukhiqizwa kwedatha yokukhiqiza

• UMBONO WE-COGONEX ANGNGNEDY "Vision On The Fly"

• Uhlelo lokuqondanisa olungezansi lwe-Pitch QFP & BGA

• Ilungele ukukhiqizwa kwevolumu encane nephakathi

• Uhlelo lwekhamera owakhelwe ngaphakathi nge-Auto Smart Fidcial Mark lokufunda

• Uhlelo lokusakaza

• Ukuhlolwa kombono ngaphambi nangemva kokukhiqizwa

• Ukuguqulwa kwe-cad Universal

• Izinga lokubekwa: 10,500 cph (IPC 9850)

• Izinhlelo ze-Ball Screw in X- kanye ne-AXES

• Ilungele i-160 ehlakaniphile ye-auto tape feeder

I-Lead-Free Reflen Oven / Lead-Free Reflew WreWersing Machine

• Isoftware yeWindows XP yokusebenza ngezindlela zamaShayina nezingesiNgisi. Lonke uhlelo olungaphansi

Ukulawulwa kokuhlanganiswa kungahlaziya nokubonisa ukwehluleka. Yonke imininingwane yokukhiqiza ingagcinwa ngokuphelele futhi ihlaziywe.

• Iyunithi yokulawula i-PC & Siemens PLC ngokusebenza okuzinzile; Ukunemba okuphezulu kokuphindaphinda kwephrofayili kungakugwema ukulahleka komkhiqizo kufakwe ekusebenzeni okungajwayelekile kwekhompyutha.

• Idizayini eyingqayizivele ye-thermal convection yezindawo zokushisa ezivela ezinhlangothini ezi-4 inikeza ukusebenza kahle kokushisa; Umehluko wokushisa okuphezulu phakathi kwezindawo ezihlangene ezi-2 ungagwema ukuphazamiseka kokushisa; Kunganciphisa umehluko wokushisa phakathi kwezingxenye ezinkulu nezincane futhi uhlangabezane nesidingo sokudambisa se-PCB eyinkimbinkimbi.

• Ukuphoqelelwa komoya okuphoqelekile noma i-chiller yokupholisa amanzi ngejubane lokupholisa elisebenzayo lifanelana nazo zonke izinhlobo ezahlukene zokuhola mahhala unamathele.

• Ukusetshenziswa kwamandla okuphansi (8-10 kWh / ihora) ukusindisa izindleko zokukhiqiza.

I-AOI (uhlelo lokuhlola okuzenzakalelayo)

I-AOI yithuluzi elibona iziphambeko ezijwayelekile ekukhiqizeni kwe-welding ezisuselwa ezimisweni ze-optical. I-AOL yiTekhnoloji yokuhlola evelayo, kepha ithuthuka ngokushesha, futhi abakhiqizi abaningi bethule imishini yokuhlola i-AL.

Ngesikhathi sokuhlola okuzenzakalelayo, umshini uskena ngokuzenzakalelayo i-PCBA ngekhamera, uqoqe izithombe, futhi uqhathanisa amalunga atholakele atholakele ngamapharamitha afanelekile database. Ukulungiswa komlungisi.

Ijubane eliphezulu, ubuchwepheshe bokucubungula okunembile okunengqondo busetshenziselwa ukuthola amaphutha ahlukahlukene okubeka kanye nokuphonswa kwamaphutha ebhodini le-PB.

Amabhodi e-PC aqala kusuka kumabhodi amakhulu we-Pitch High-density kuya emabhodini amakhulu asayizi omkhulu, ukuhlinzeka ngezixazululo zokuhlola ezi-inthanethi ukwenza ngcono ukusebenza kahle kokukhiqiza nekhwalithi ye-solder.

Ngokusebenzisa i-AOL njengethuluzi lokunciphisa iphutha, amaphutha angatholakala futhi aqedwe ekuqaleni inqubo yomhlangano, okuholele ekuphatheni okuhle kwenqubo. Ukutholwa kusenesikhathi kweziphambeko kuzovimbela amabhodi amabi ukuthi athunyelwe ezigabeni zomhlangano ezalandela. I-AI izonciphisa izindleko zokulungisa futhi igweme amabhodi okubhidliza ngaphezu kokulungiswa.

I-3D X-ray

Ngokuthuthuka okusheshayo kobuchwepheshe bama-elekthronikhi, ukufakwa okuncane, umhlangano onobunzima, kanye nokuvela okuqhubekayo kobuchwepheshe obusha bokupakisha, izidingo zekhwalithi yomhlangano wesifunda zikhula ziphakeme futhi ziphakeme.

Ngakho-ke, izidingo eziphakeme zibekwa ezindleleni zokutholwa nobuchwepheshe.

Ukuze uhlangabezane nale mfuneko, ubuchwepheshe obusha bokuhlola buhlala buvela njalo, futhi ubuchwepheshe bokuhlola othomathikhi we-3D othomathikhi ungummeleli ojwayelekile.

Akunakuthola kuphela amalunga angenakuthola amalunga, njenge-BGA (I-Ball Grid Array, Iphakethe le-Ball Grid Aray), njll.

Njengamanje, kufakwa amasu ahlukahlukene okuhlola emkhakheni wokuhlolwa komhlangano we-elekthronikhi.

Ukuhlinzekwa okujwayelekile kungukuhlola okubukwayo okubhaliwe (MVI), umhloli wesekethe (i-ICT), kanye nokuzenzakalelayo okuzenzakalelayo

Ukuhlola (ukuhlolwa okuzenzakalelayo okuzenzakalelayo). I-AI), ukuhlolwa kwe-x-ray okuzenzakalelayo (axi), umhloli osebenzayo (ft) njll.

Isiteshi se-PCBA Rewall

Ngokuya ngenqubo yokuhlanzana yawo wonke umhlangano we-SMT ukhathazekile, ingahlukaniswa ngezinyathelo eziningana ezinjenge-depolder, ukubhekisisa kabusha kwengxenye, ukuhlanza kwePCB Pad, ukubekwa kwengxenye, ukubekwa.

1. Ukuqunjelwa: Le nqubo ukususa izakhi ezilungisiwe kwi-PB yezakhi ezihleliwe ze-SMT. Isimiso esiyisisekelo kunazo zonke akusona kulimaza noma silimaze izingxenye ezisusiwe ngokwazo, izingxenye ezizungezile kanye namaphini e-PCB.

2

3. I-PCB Pad Cleaning: PCB Pad Cleaning ifaka umsebenzi wokuhlanza kanye nokuqondanisa. I-Pad Level evame ukubhekisela ekulinganiseni kwe-PCB Pad Race of the Diep. Ukuhlanza kwePad kuvame ukusebenzisa umthengisi. Ithuluzi lokuhlanza, njengensimbi elungiselelwe, lisusa umthengisi osele kusuka kumaphilisi, bese kusula ngotshwala ngokuphelele noma i-solvent evunyelwe ukususa izinhlawulo nezingxenye ezisele ze-flux.

4. Ukubekwa Kwezakhi: Hlola i-PCB ephindele kabusha nge-asches ephrintiwe solder; Sebenzisa idivaysi yokubekwa kwengxenye yesiteshi sokusebenza ukuze ukhethe i-vacuum nozzle efanelekile bese ulungisa i-PCB ye-rework ukuthi ibekwe.

5 Idinga ukucatshangelwa ngokucophelela ngokusekelwe kwizakhiwo zezakhiwo ze-PB, kanye nezakhiwo zezinto ezisetshenziswayo ezisetshenzisiwe. I-Welding ye-Manual ilula futhi isetshenziselwa kakhulu ukuphinda i-relding yezingxenye ezincane.

Umshini wokuthengisa wamahhala we-lead-free wave

• Ukuthinta kwe-Touch Screen + PLC Control Unit, ukusebenza okulula nokuthembekile.

• Idizayini yangaphandle eqondisiwe, ukwakheka kwangaphakathi modular, hhayi okuhle kuphela kodwa futhi kulula ukuyigcina.

• Isifutho seFlux sikhiqiza i-atomization enhle ngokusetshenziswa okuphansi okuphansi.

• Ukuphelelwa phansi kwe-turbo fan nge-curtain evikela ukuvikela ukuguquguquka kwe-atomoled flux ku-peheating zone, uqinisekise ukusebenza okuphephile.

• Ukuqala ukusebenza kwe-heather ye-heater kulungele ukulungiswa; I-PID control heating, izinga lokushisa elizinzile, ijika elibushelelezi, xazulula ubunzima benqubo engenamsebenzi.

• I-Soler Pans esebenzisa amandla aphezulu, i-nensimbi engekho emthethweni ikhiqiza ukusebenza kahle okuphezulu okushisayo.

Ama-nozzles enziwe nge-titanium aqinisekisa ukungaguquki okuphansi okushisayo kanye ne-oxidation ephansi.

• Inomsebenzi wokuqalisa isikhathi esizenzakalelayo nesikhathi sokuvalwa komshini wonke.