Iphaneli ye-PCBImithetho nezindlela

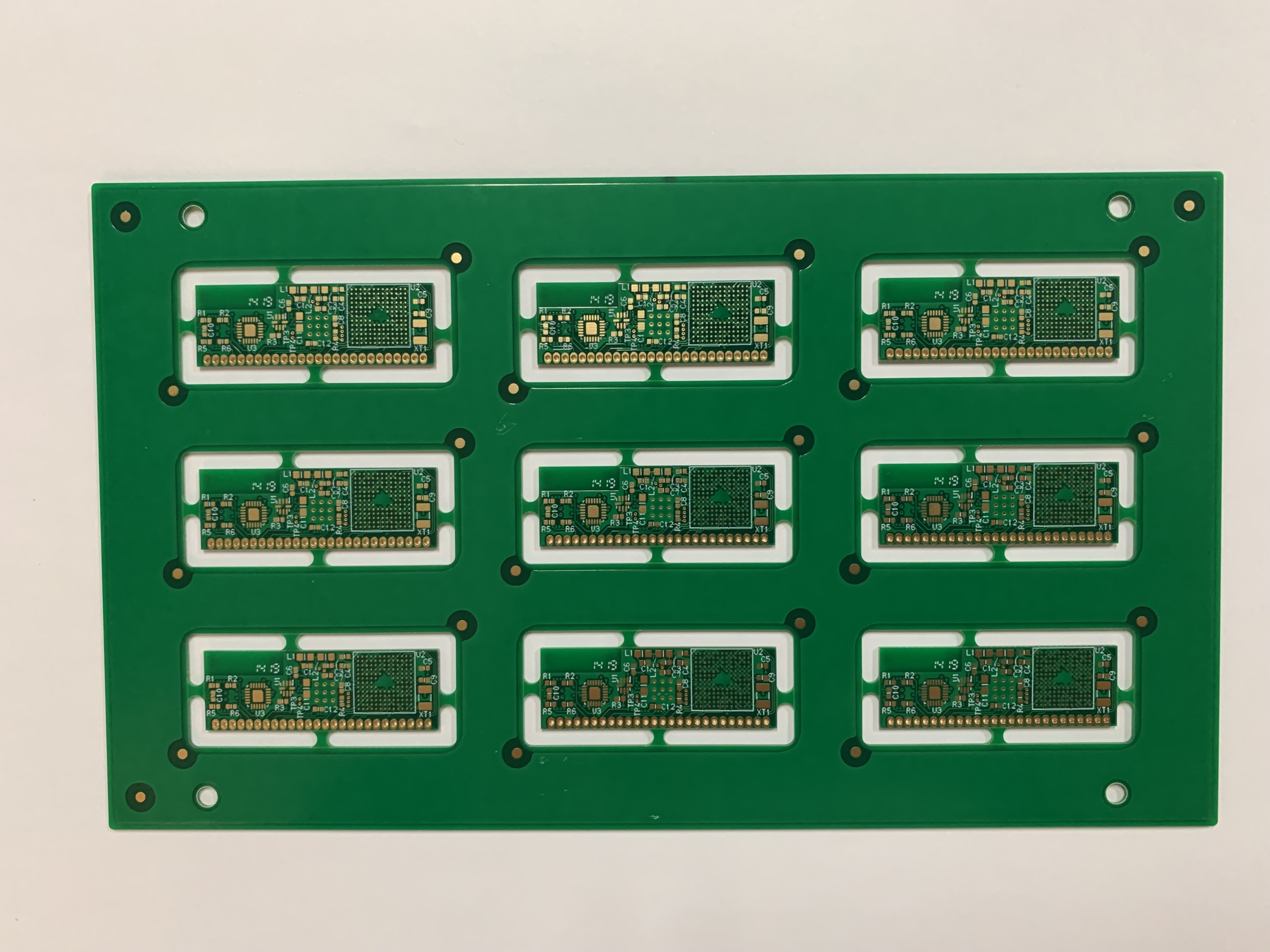

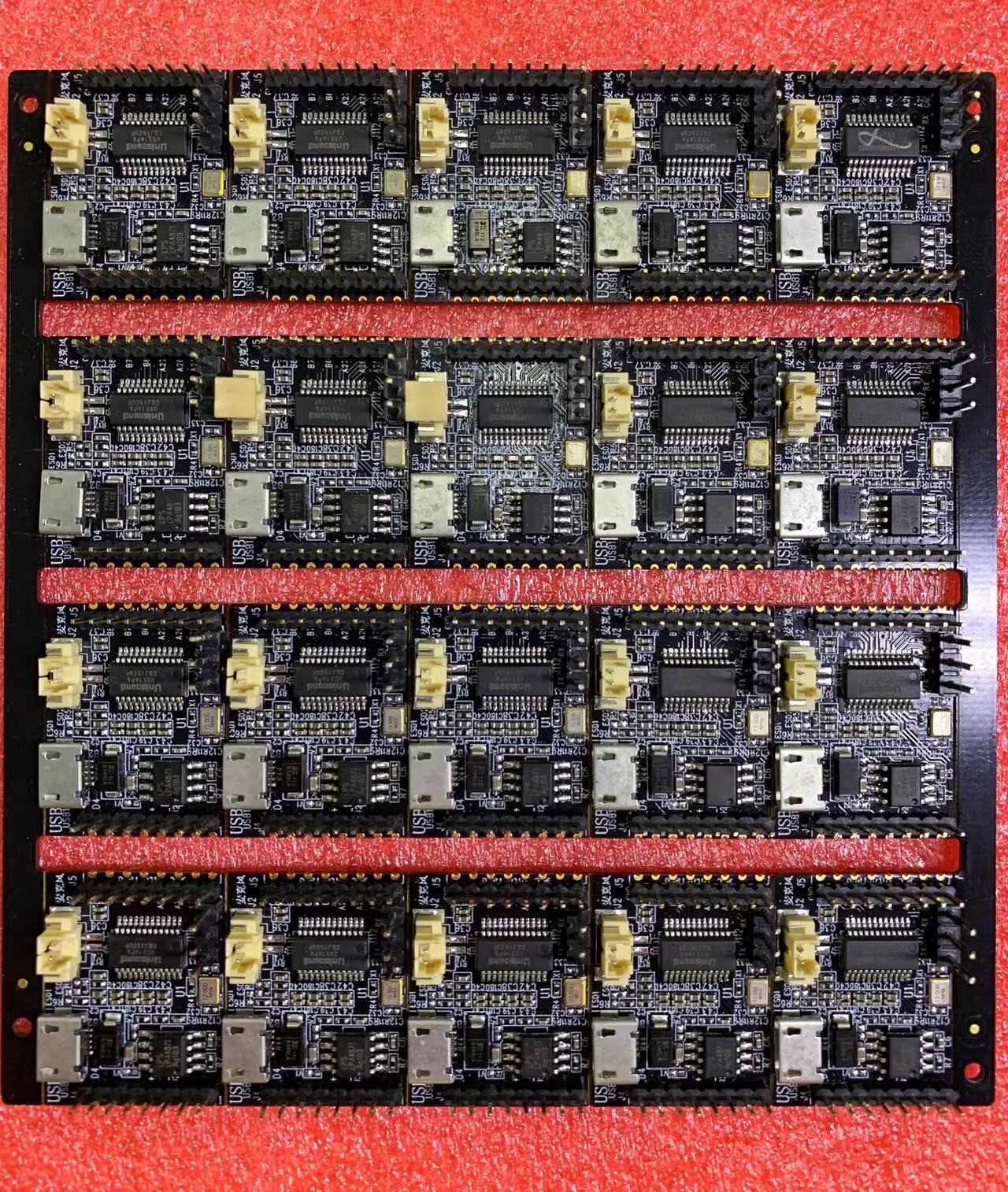

1. Ngokwezidingo zenqubo zoMsethandlela ohlukile womhlangano, usayizi omkhulu kanye nosayizi omncane wephaneli kufanele uqondakale kahle. Ngokuvamile, i-PCB incane kune-80x80mm idinga ukuphazamiseka, futhi ubukhulu obukhulu buya ngesilinganiso sokucubungula kwefektri. Ngamafuphi, usayizi we-PCB kufanele ahlangabezane nesidingo seImishini ye-SMTUkufakelwa, okulungele ukucubungula kwe-SMT Patch futhi kusize ukunquma ubukhulu bebhodi le-PCB.

2. Umhlangano kanye nokugibela okuphansi kufanele kuhlangabezane nezidingo ze-DFM ne-DFA, futhi ngasikhathi sinye kuqinisekise ukuthi umhlangano we-PCB uhleliwe futhi awukhubazeki kalula ngemuva kokufakwa kwiventu. I-groovo ehlukanisa phakathi kwamaphaneli kufanele ihlangabezane nezidingo zeflethi yobuso ngesikhathiI-PCBAUkucubungula chip.

3. KuPCB Panelukusongoza icebo, ukuhlelwa kwezakhi kufanele kugweme ukwehlukanisa ukucindezela futhi kubangele imifantu yezakhi. Ukusetshenziswa kwesakhiwo sephaneli esakwaziswa kwangaphambili kunganciphisa i-warpage kanye ne-deformation ngesikhathi sokwehlukana kwebhodi, futhi kunciphise ukucindezelwa kwezakhi. Ubuncane, zama ukungafaki okubalulekileizingxenyeOlandelayoohlangothini lwenqubo.

I-4. Usayizi kanye nefomu lephaneli liphathwa ngokusho kwephrojekthi ethile, futhi ukwakheka kokubukeka kusondelene nesikwele ngangokunokwenzeka. Kunconywe ngokuqinile ukusebenzisa indlela engu-2 × 2 noma 3 × 3 3. Akunconyelwe ukuhlanganisa amaphaneli we-yin nama-yang uma kungadingekile;

5ngemuva kokufudumala.

6 Musa ukubeka amaphoyinti wereferensi ngokulinganayo, ukuze uhlangothi olubuyela emuva / olubuyela emuva lwe-PCB lungangena emshinini ngokusebenzisa umsebenzi obonakalayo wedivayisi uqobo.

7. Lapho ubukhulu beI-PCB BoardIngaphansi kwe-1.0mm, amandla ebhodini lephaneli lonke azoncishiswa kakhulu (abuthakathaka) lapho kungezwa amandla okuhlangene noma i-v-cut cleth kungu-1/3 wokuxhaswa kwe-PCB - okubangelwa yi-PCB fiber v ephukile, okuholela ekuthandeni okuthe xaxa kwamandla. Uma ingasekelwa yi-jig, izothinta inqubo engezansi kwe-PCBA.

8. Lapho kukhonaiminwe yegolideKu-PCB, ngokuvamile faka iminwe yegolide ngaphandle kweBhodi elibheke endaweni engeyona eye-Splint. Unqenqema lomunwe wegolide alunakuhlukaniswa noma lucutshungulwe.

UShenzhen Angeke PCB Co, LTD

Isikhathi Sokuthumela: APR-04-2023