Imeyili:info@anke-pcb.com

WhatApp / WeChat: 008618589033832

Skype: Sannyduanbsp

Izici ezintathu ukuvikela ubuqotho bamandla ngaphakathiUkuklanywa kwe-PCB

Ekwakhiweni kwama-elekthronikhi kwanamuhla, ubuqotho bamandla yingxenye ebaluleke kakhulu ye-PCB Design. Ukuqinisekisa ukusebenza okuzinzile kanye nokwenza ukusebenza kwamadivayisi kagesi, kufanele sikucabangele futhi siklame ngokuphelele kusuka kumthombo wamandla waya komukeli.

Ngokuklama ngokucophelela nokwandisa amamojula wamandla, izindiza ezingqimba zangaphakathi, nama-chips okuhambisa amandla singakwazi ukufeza ubuqotho bamandla ngempela. Le ndatshana izongena kulezi zinto ezintathu ezibalulekile ukuhlinzeka ukuholwa namasu okusebenzayo kwabaqambi be-PCB.

I. I-Power Module Layout Wiring

Imodyuli yamandla ingumthombo wamandla wawo wonke amadivaysi kagesi, ukusebenza kwawo kanye nokwakheka okuthinta ngqo ukuqina kanye nokusebenza kahle kwalo lonke uhlelo. Isakhiwo esifanele kanye nokuzilahla ngeke kunciphise ukungenelela komsindo kepha futhi kuqinisekisa ukuhamba okubushelelezi, ngaleyo ndlela kuthuthukiswe ukusebenza okuphelele.

Ukuhlelwa kwe-module

1.Source Ukucubungula:

Imodyuli yamandla kufanele inake ngokukhethekile njengoba isebenza njengendawo yokuqala yamandla. Ukwehlisa Isingeniso Somsindo, imvelo ezungeze imodyuli yamandla kufanele igcinwe ihlanzekile ngangokunokwenzeka ukugwema ukwakheka kokunyeimvamisa ephezulunoma izingxenye ezibucayi zomsindo.

2.Clower Power Supply Chip:

Imodyuli yamandla kufanele ibekwe eduze kwe-chip enikezwe amandla ngangokunokwenzeka. Lokhu kunganciphisa ukulahleka kwinqubo yamanje yokuhambisa futhi kunciphise izidingo zendawo yendiza yangaphakathi yesendlalelo.

I-Efrenitation yokuqagela:

Imodyuli yamandla ingakhipha ukushisa ngesikhathi sokusebenza, ngakho-ke kufanele kuqinisekiswe ukuthi akukho okuvinjezelwa ngaphezulu kwe-IT ngokuvimbela ukushisa. Uma kunesidingo, ama-heatinks noma abalandeli bangangezwa ngokupholisa.

Ama-loops angu-4.Avoiding:

Lapho ujikeleza, gwema ukwakha izihibe zamanje ukunciphisa amathuba okuphazanyiswa kwe-electromagnete.

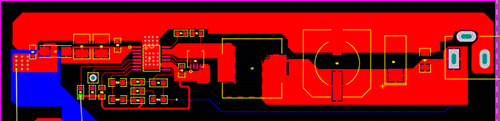

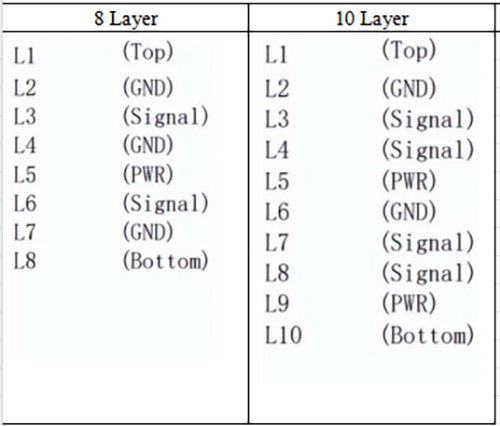

II. Ukuhlelwa Kwezindiza Yangaphakathi Kwefayeri

A. I-Laser Stack Design

In Idizayini ye-PCB EMC, I-Layer Stack Design iyinto esemqoka edinga ukucubungula umzila nokusatshalaliswa kwamandla.

a. Ukuqinisekisa izici eziphansi zokubulawa kwendiza yamandla nokuhlangana komhlabathi womhlaba, ibanga eliphakathi kwamandla nezindiza zomhlaba akufanele lidlule ku-10mil, ngokuvamile kunconywe ukuba ngaphansi kwama-5mil.

b. Uma indiza yamandla eyodwa ingasebenzi, ungqimba olungaphezulu lungasetshenziswa ukubeka indiza yamandla. Amandla asondelene namandla asondelene namandla aphansi akha i-capacitor yendiza enomqondo omncane we-AC kanye nezimpawu ezinhle kakhulu zemvamisa.

c. Gwema izendlalelo zamandla amabili eziseduze, ikakhulukazi ngomehluko omkhulu wevota, ukuvikela ukuhlanganiswa komsindo. Uma kungenakugwenywa, kwandise ukuhlukaniswa kwezikhala phakathi kwalezi zingqimba zamandla ezimbili ngangokunokwenzeka.

d. Izindiza Zereferensi, ikakhulukazi izindiza zamandla okubhekisisa amandla, kufanele zilondoloze izici eziphansi zokuvimbela futhi zingalungiswa ngama-paracitors we-bypass kanye nokulungiswa kwesendlalelo.

B.Multiple Power Segmentation

a. Ngemithombo ethile yamandla amancane amancane, njenge-voltage esebenza ngokusebenza kwe-Chip ethile ye-IC, ithusi kufanele libekwe engxenyeni yesiginali ukuze iqinisekise ubuqotho bendiza yamandla, kepha gwema ukubeka amandla ithusi ngaphezulu kwesendlalelo somoya.

b. Ukukhethwa kobubanzi bokuhlukaniswa kufanele kube kufanelekile. Lapho i-voltage inkulu kune-12V, ububanzi bungaba ngu-20-30mil; Ngaphandle kwalokho, khetha u-12-20mil. Ububanzi bengxenye phakathi kwemithombo yamandla ye-analog ne-digital kudingeka inyuswe ukuvikela amandla edijithali ekuphazamisezeleni ngamandla we-analog.

c. Amanethiwekhi wamandla alula kufanele aqedwe engxenyeni yomzila, futhi amanethiwekhi wamandla amade kufanele abe nama-capacito ehlunga angeziwe.

d. Indiza yamandla ehlukanisiwe kufanele igcinwe njalo ukugwema ukwakheka okungajwayelekile okubangela ukuphindisela kanye nokukhulisa amandla amandla. Imichilo emide futhi emincane kanye nokwahlukana okumiswe njengembumba akuvunyelwe.

C.Plane FINTION

a. Indiza yamandla kufanele ihlanganiswe eduze nendiza yomhlabathi.

b. Ama-chips anokusebenza okuphezulu okudlula ama-500mhz, ngokuyinhloko athembele ekuhlunga kwendiza yokuhlunga futhi usebenzise inhlanganisela yokuhlunga kwe-capacitor. Umphumela wokuhlunga udinga ukuqinisekiswa yi-Power Contherlity Simulation.

c. Faka ama-inductors ama-capacitors wokuwa asongelwa endizeni yokulawula, njengokukhula kwe-capacitor eholela kanye nokwanda kwe-vapacitor vias, ukuqinisekisa ukuthi amandla aphansi we-capacitor aphansi kunombhekisi.

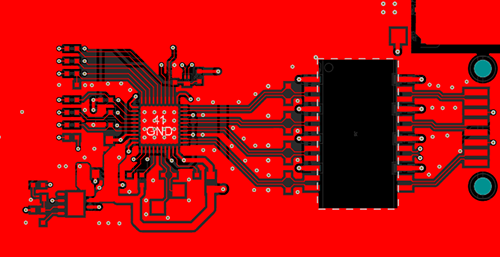

III. I-Power Chip Layout Wiring

I-Chip Power ingumongo we-elekthronikhi, kanye nokuqinisekisa ukuthembeka kwayo kwamandla kubalulekile ekuthuthukiseni ukusebenza kwensiza nokuqina. Ukulawulwa kobuqotho bamandla kwama-Chips Amandla ikakhulukazi kubandakanya ukuphathwa komzila we-Chip Power Pins kanye nesakhiwo esifanele kanye nokuqashwa kwama-capacitors. Lokhu okulandelayo kuzocacisa imininingwane kanye neseluleko esisebenzayo maqondana nalezi zici.

Umzila we-A.Chip Power Pin

Umzila we-Chip Power Pins uyingxenye ebalulekile yokulawulwa kobuqotho bamandla. Ukuhlinzeka ngokuhlinzekwa kwamanje okuzinzile, kunconywa ukukhulisa umzila wezikhonkwane zamandla, ngokuvamile kuya kobubanzi obufanayo nezikhonkwane ze-chip. Imvamisa,Ububanzi obuncaneAkufanele ibe ngaphansi kwama-8mil, kepha ngemiphumela engcono, zama ukufeza ububanzi be-10mil. Ngokwengeza ububanzi bomzila, ukungcola kungancishiswa, ngaleyo ndlela kunciphise umsindo wamandla futhi kuqinisekiswe ukuhanjiswa kwanele kwamanje ku-chip.

B.Layout kanye nomzila wama-capacitors wokuwa

Ama-capacitors aqothulayo adlala indima ebalulekile kulawulo lobuqotho lwamandla ama-Chips Amandla. Ngokuya ngezimpawu ze-capacitor kanye nezidingo zohlelo lokusebenza, ama-capacitors aqamba ama-capaciapling ahlukaniswe ngama-capacitors amakhulu namancane.

a. Ama-capacitor amakhulu: Ama-capacitors amakhulu ajwayele ukusatshalaliswa ngokulinganayo ku-chip. Ngenxa yemvamisa yabo ephansi kanye nemisebe enkulu yokuhlunga, ingahlunga ngempumelelo umsindo ophansi kakhulu futhi inikeze ukunikezwa kwamandla okuzinzile.

b. Ama-capacitors amancane: Ama-capacitor amancane anemvamisa ephakeme ye-resonant kanye ne-radius emincane yokuhlunga, ngakho-ke kufanele ibekwe eduze ngangokunokwenzeka kwizikhonkwane ze-chip. Ukuzibeka kude kakhulu kungenzeka kungahle kungahlunga ngempumelelo umsindo wemvamisa ephezulu, kulahlekelwe umphumela wokukhohlisa. Ukuhlelwa okulungile kuqinisekisa ukuthi ukusebenza kwama-capacitors amancane ekuhlungeleni umsindo wemvamisa ephezulu kusetshenziswe ngokuphelele.

C.Wiring indlela yama-capacitors aqothulayo afanayo

Ukuqhubeka nokwenza ngcono ubuqotho bamandla, ama-capacitors amaningi wokukhohlisa avame ukuxhumeka ngokufana. Inhloso esemqoka yalo mkhuba ukunciphisa ukunciphisa i-extansing engeziwe (i-ESL) ye-capacitors yomuntu ngamunye ngokusebenzisa ukuxhumana okufanayo.

Lapho ubheka ama-capacitors amaningi wokukhohlisa, ukunakwa kufanele kukhokhwe ekubekweni kwama-vias ama-capacitors. Umkhuba ojwayelekile ukususa i-vias yamandla nangomhlaba. Inhloso esemqoka yalokhu ukunciphisa ukwehla kokuhlangana phakathi kwama-capacitors ahlabelelayo. Qinisekisa ukuthi ukungena kwe-mutuctance kuncane kakhulu kune-esl ye-capacitor eyodwa, ukuze ukuqubuka kwe-ESL jikelele ngemuva kokufana kwama-capacitors amaningi okukhohlisa kungu-1 / n. Ngokunciphisa ukuncishiswa, ukulungiswa kokuhlunga kungathuthukiswa ngempumelelo, ukuqinisekisa ukuqina kwamandla okuthuthukile.

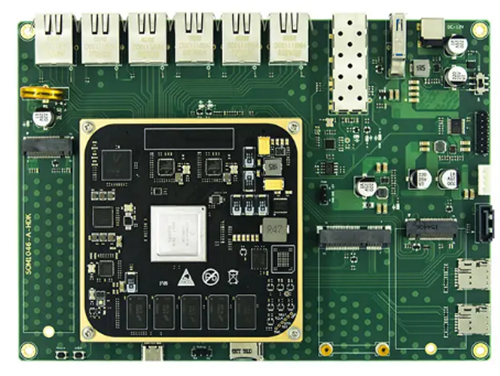

Isakhiwokanye nomzila wamamojula wamandla, ukuhlela okuyi-Layer Ungqimba lwe-Plane design, kanye nokuphathwa kahle kwe-Power Chip Layout kanye ne-wiring kubaluleke kakhulu ekwakhiweni kwamadivayisi we-elekthronikhi. Ngokuhlelwa okufanele kanye nomzila, singaqinisekisa ukuqina kanye nokusebenza kwamamojula wamandla, kunciphise ukuphazamiseka komsindo, futhi kuthuthukiswe ukusebenza okuphelele. Idizayini yengqimba yesendlalelo kanye nengxenye yamandla amaningi abuye asebenze kahle izici zezindiza zamandla, ukunciphisa ukuphazamiseka komsindo wamandla. Ukuphathwa okufanele kwe-Power Chip Layout kanye ne-wiring kanye nama-capacitors okuhlalisana kubalulekile ukuthi kulawulwa ubuqotho bamandla, kuqinisekisa ukuhlinzekwa kwamanje okuzinzile nokuhlunga komsindo okusebenzayo, ukuthuthukisa ukusebenza kwensiza nokuqina.

Ekusebenzeni okusebenzayo, izinto ezahlukahlukene ezifana nobukhulu obukhona, ububanzi bomzila, inani le-vias, imiphumela yokuhlangana, njll. Landela ukucaciswa kwe-Design kanye nemikhuba emihle kakhulu yokuqinisekisa ukulawulwa nokwenza kahle amandla okuthembeka. Ngale ndlela kuphela esingakunikeza ukuhlinzekwa kwamandla okuzinzile futhi okusebenzayo kwamadivayisi kagesi, ahlangabezane nezidingo ezikhulayo zokusebenza, futhi ziqhube ukuthuthukiswa kanye nenqubekela phambili yobuchwepheshe bama-elekthronikhi.

UShenzhen Angeke PCB Co, LTD

Isikhathi sePosi: Mar-25-2024