Izici ezinhlanu eziyisisekelo zokuphathwa kokuthengwa kwezidingo

Amalungiselelo

Uhlelo luyisigaba sokuqala, futhi zonke izinsiza kufanele zihlelelwe ngaphambi kwesikhathi ukuze zihlangabezane nezidingo zamakhasimende futhi zifinyelele ukusebenza okulindelekile.

Ukugoqa

Khetha abahlinzeki abahle nabafanelekile futhi uphathe ubuhlobo babo. Kulesi sigaba, ezinye izinqubo kufanele futhi zisungulwe ukuze zilawule ukuthengwa, ukuphathwa kokusungula kanye nokukhokha.

Ukukhiqiza

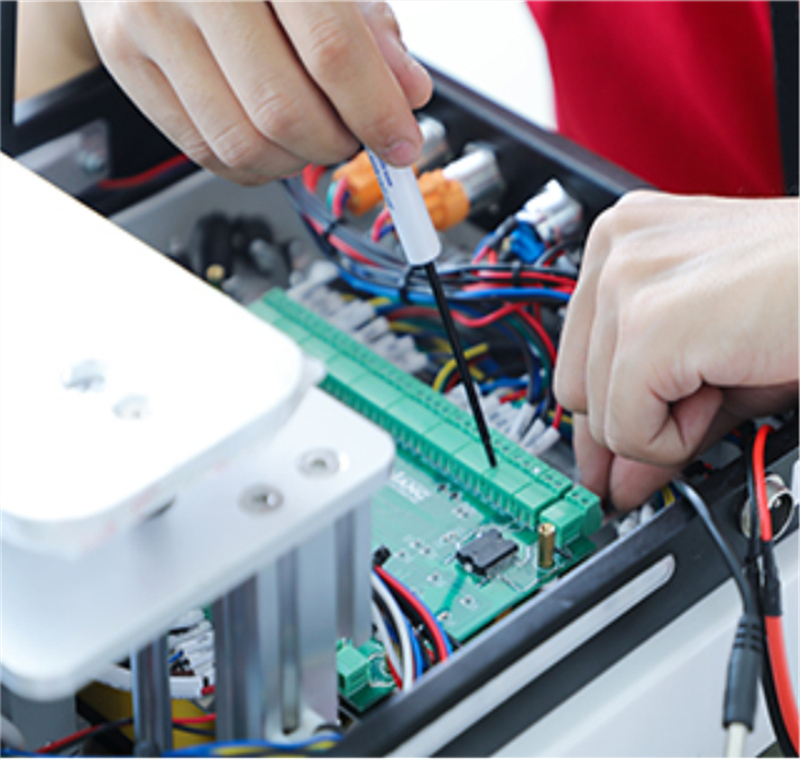

Imisebenzi edingekayo enhlanganweni, efana nezinto zokwakha eziluhlaza, ukukhiqiza umkhiqizo, ukuhlolwa kwekhwalithi, ukupakishwa kwezinto zokuhamba kanye nohlelo lokulethwa kanye nohlelo lokulethwa.

Ukuhambisa

Hlela ama-oda wamakhasimende, hlela ukulethwa, ukuhambisa izimpahla, ama-invoice ama-invoice bese ukhokhela amakhasimende.

-Buyisa

Hlakulela inethiwekhi esekela imikhiqizo yokutakula, kufaka phakathi imikhiqizo enephutha nemikhiqizo eyengeziwe. Lesi sigaba futhi sisho ekusukeni kokusungula kanye nokuphathwa kokuhamba.

Izici ezi-4 zokuphathwa ngempumelelo kwempahla

Ukucaca

Ukusobala kokuphathwa kokuthengwa kwezidingo kusho ukuthi isixhumanisi ngasinye singabelana ngokukhululekile imininingwane, ebalulekile ezindlekweni zokuphatha nokwaneliseka. Kungakha ukwethembana phakathi kwabalingani bamathempeli okuhlinzekwayo, kungagcina sekusungulwe ubudlelwano obuqinile nobunokwethenjelwa ukusekela ukusebenza kwalo lonke i-chain etholakalayo.

Ukuxhumana okufika ngesikhathi

Ukuxhumana okuhle kuqinisekisa ukuthi zonke izixhumanisi ezikule mpahla zizosebenza kahle. Kungakugwema izinkinga eziningi, njengokulahlekelwa yizimpahla namakhasimende angagculisekile. Noma ngabe kukhona ezinye izinguquko noma izinkinga ku-Supply Chain, inkampani ingaphendula ngokushesha.

Ukuphathwa Kwengozi

Ngesikhathi sokusebenza kwempahla etholakalayo, izingozi noma izinkinga ezintsha kuzokwenzeka nakanjani, ngakho-ke amandla okubhekana nezimo eziphuthumayo kubalulekile. Ukuphathwa okusebenzayo kokuhlinzekwa kwempahla kungalungiselela uhlelo oluphuthumayo olusemthethweni ngokushesha okukhulu, olungasetshenziswa ngokushesha futhi ekugcineni luxazulule inkinga.

Ukuhlaziywa nokubikezela

Ukuphathwa okusebenzayo kokuhlinzekwa kwempahla kungahlaziya isimo samanje sebhizinisi, kufaka phakathi amandla alo nobubi. Ngaphezu kwalokho, kungasiza ukubikezela izidingo zamakhasimende. Ngakho-ke, ungakha amacebo okukhiqiza ngokuzayo kusengaphambili, okuwusizo ekuthuthukisweni okuqhubekayo kwamabhizinisi.

Si-oda kwinkokhelo yakho eqondile yoku-oda kwezinto ezibonakalayo 5% noma i-5 eyengeziwe yezinto eziningi. Ngesinye isikhathi sibhekene nama-oda okungenani / ama-oda amaningi lapho kufanele kuthengwe khona izinto ezengeziwe. Lezi zingxenye ziyabhekiswa, futhi kuvunyelwe ukutholwa kwikhasimende lethu ngaphambi koku-oda.

U-Anse angasiza ukubamba ukusungulwa, kepha ngeke sibambele izingxenye kwinkokhelo yakho yezinto ezibonakalayo esivele sinazo. Singasikisela ama-Strondes noma sisize ngokukhethwa kwengxenye uma kunesidingo, kepha sizothumela ishidi ledatha ukuze lidinge ukuvunywa kwamakhasimende ngaphambi koku-oda.

Isikhathi sokuhola se-1.procument kungenjalo ngaphezu kwezikhathi zokuhola zomhlangano.

2.Uma si-oda amabhodi wesifunda, ezimweni eziningi leli yisikhathi eside kunazo zonke sokuhola, futhi sinqunywa yizidingo zamakhasimende.

3.ALL Izakhi kumele zitholwe ngaphambi kokuqala ingxenye yomhlangano we-oda.

Yebo, kuya ngezicelo zeklayenti, singakwazi uku-oda nje lokho okudingayo ukuthi sikunikeze, futhi ungakwazi ukunikeza okunye. Sibhekisa kulolu hlobo lwe-oda njengomsebenzi okhiye we-Turn-Key.

Izakhi ezinezidingo eziphansi zokuthenga zibuyiswa ngama-PCB aqediwe noma i-pandawill isiza ukubamba inventory njengoba iceliwe. Zonke ezinye izinto azibuyiswa kwikhasimende.

I-1.Bill yezinto ezibonakalayo, ephelele ngolwazi ngefomethi ye-Excel.

Imininingwane ye-2.Compfete ifaka phakathi - igama lomenzi, inombolo yengxenye, abaqambi abakhethiweyo, incazelo yengxenye, ubungako.

3.coplote amafayela we-gerber.

Idatha ye-4.Centroid - Leli fayela lingadalwa yi-ANKE uma kudingeka.

I-5.flashing noma izinqubo zokuhlola nemishini uma idinga u-Anke ukwenza ukuhlolwa kokugcina.

Amaphakeji we-SMT e-SMT amunca inani elincane lomswakama ngokuhamba kwesikhathi. Lapho lezi zingxenye zidlula kuhhavini ziveza, lowo umswakama ungakhula futhi ulimaze noma uchithe i-chip. Kwesinye isikhathi ukulimala kungabonakala ngamehlo. Kwesinye isikhathi awukwazi ukukubona nakancane. Uma sidinga ukubhaka izakhi zakho, umsebenzi wakho ungabambezeleka ngamahora angama-48. Lesi sikhathi sokubhaka ngeke sibheke isikhathi sakho sokuphenduka.

2.Silandela iJDEC J-STD-033B.1 Standard.

3.Kusho lokho ukuthi uma ingxenye yelebuli ifakwe njengomuntu onobuhlakani noma ovulekile futhi ongathandeki, sizonquma ukuthi kudingeka ukuthi kubhakwe ukuthi kudingeka kubhakwe yini uma kudingeka kubhakwe uma kudingeka kubhakwe ukuthi kudingeka kubhakwe yini.

I-4.on 5 no-10 usuku luphenduka, lokhu mhlawumbe ngeke kubangele ukubambezeleka.

Imisebenzi engama-5.E-24 no-48 yehora, isidingo sokubhaka izingxenye sizodala ukubambezeleka kwamahora angama-48 ngeke kubalwe endaweni yakho ye-TUNE.

6.Uma kungenzeka, sithumele njalo izingxenye zakho ezivalwe uphawu lapho uzitholile.

Isikhwama ngasinye, ugqoko, njll. Kufanele imakwe ngokucacile ngenombolo yengxenye efakwe kuhlu lwakho lwezinto zokwakha.

I-1.ikuncike kwinkonzo yomhlangano owukhethayo, singasebenza ngetheyiphu yokusika yanoma yibuphi ubude, amashubhu, ama-reels namathileyi. Sicabanga ukuthi kuzothathwa ukunakekelwa ukuze kuvikelwe ubuqotho bezakhi.

Izakhi ze-2.Am zinomswakama noma zibucayi, sicela iphakheji ngokufanele ku-static elawulwa futhi / noma ukufakwa okuvalwe uphawu.

Izakhi ze-3.SMT ezinikezwe okuxekethile noma ngobuningi kufanele zibhekwe njengokubekwa kwe-thru-umgodi. Kufanele ngaso sonke isikhathi uqinisekise nathi kuqala ngaphambi kokucaphuna umsebenzi ngezakhi ezixegayo ze-SMT. Ukuthumela okukhululekile kungadala ukulimala futhi kungakubiza okungeziwe ekusingatheni. Cishe kuhlale kubiza kakhulu ukuthenga umucu omusha wezakhi ke ukuze sizame ukuba sizame futhi sizisebenzise.

Ukuphathwa kwezingxenye