Imikhiqizo

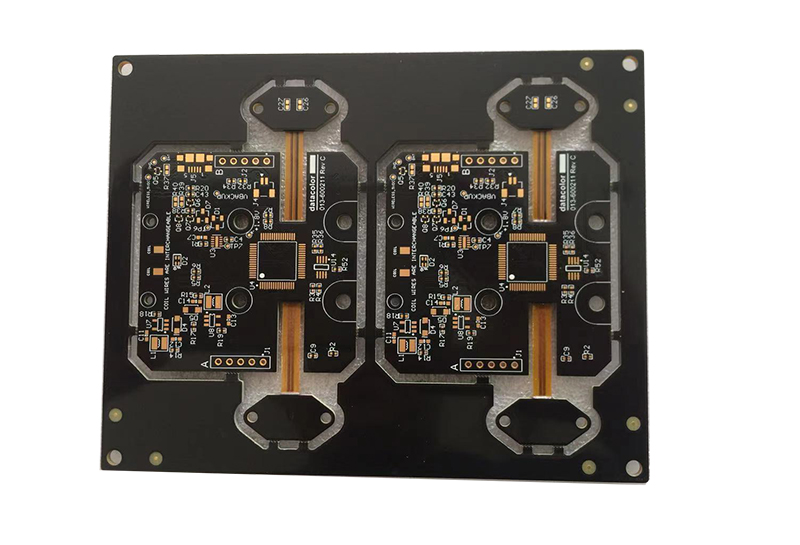

Inzwa ye-Industrost 4 ungqimba oluqinile & i-PCB ye-PCB nge-2oz yethusi

| Izebele | Izingqimba ezi-4 ziqinile + 2 izingqimba zishintshana |

| Ukuqina kwebhodi | I-1.60mm + 0.2mm |

| Into uqobo lwayo | Fr4 TG150 + I-polymmide |

| Ubukhulu bethusi | 1 oz (35um) |

| Qeda phezulu | Ubukhulu be-enig au 1um; NI ubukhulu 3um |

| Min Hole (MM) | 0.21mm |

| Ububanzi bemigqa yeminithi (mm) | 0.15mm |

| Isikhala se-Min Line (MM) | 0.15mm |

| Imaski yomthengisi | -Yimpatho |

| Umbala we-legend | Okumhlophe |

| Ukucutshungulwa kwemishini | I-V-CORES, CNC Milling (Umzila) |

| Ukufaka ndawonye | Isikhwama se-Anti-Static |

| Ukuhlola | Ukundiza kwendiza noma ukuhlanganiswa |

| Ukwamukelwa okujwayelekile | I-IPC-A-600H CLASS 2 |

| Isicelo | Izithuthi Zokwe-Electronive |

Ukuqalisa

Ama-PC aqinile & aguquguqukayo ahlanganiswe namabhodi aqinile ukudala lo mkhiqizo we-hybrid. Ezinye izingqimba zenqubo yokukhiqiza zifaka umjikelezo oguqukayo odlula emabhodini aqinile, afana

Umklamo wesifunda esijwayelekile we-Hardboard.

Umklami weBhodi uzokwengeza ama-plated ngokusebenzisa izimbobo (PTHS) exhumanisa amasekethe aqinile futhi aguquguqukayo njengengxenye yale nqubo. Le PCB yayithandwa ngenxa yobuhlakani bayo, ukunemba, nokuvumelana nezimo.

I-Rigid-Flex PCBS yenza lula ukwakheka kwe-elekthronikhi ngokususa izintambo eziguqukayo, ukuxhumana, kanye ne-wiring yomuntu ngamunye. I-Rigid & Flex Boards Circleitry ihlanganiswe kakhulu esakhiweni seBhodi sonke, esithuthukisa ukusebenza kukagesi.

Onjiniyela bangalindela ukugcinwa okungcono kakhulu kanye nokusebenza kukagesi ngenxa yokuxhumeka kwangaphakathi kwe-PCB ye-PCB kanye nokuxhumeka kwemishini.

Into uqobo lwayo

Izinto zokwakha ezingaphansi

Into ethandwa kakhulu ye-rivid-ex iyi-fiberglass. Ungqimba oluwugqinsi lwe-epoxy resin amajazi le fiberglass.

Noma kunjalo, i-fiberglass efakwe nge-epoxy-efakiwe ayiqinisekile. Ayikwazi ukumelana nokushaqeka okungazelelwe nokuqinile.

Polyomide

Lokhu okuqukethwe kukhethwa ukuze kuguqulwe kwayo. Iqinile futhi ingamelana nokushaqeka nokushuka.

I-polyomide nayo ingamelana nokushisa. Lokhu kwenza kube kuhle ngezicelo zokushintshashintsha kwezinga lokushisa.

I-Polyester (Pet)

I-PET ithandeka izici zayo zikagesi nokuvumelana nezimo. Iphikisana namakhemikhali nokudangala. Kungasetshenziswa ngenxa yezimo ezinzima zezimboni.

Sebenzisa i-substrate efanelekile kuqinisekisa amandla afiselekayo nokuphila isikhathi eside. Ibheka izinto ezifana nokumelana nezinga lokushisa kanye nokuqina kwesici ngenkathi ukhetha i-substrate.

Izinamathela ezinama-polymide

Ukushisa kokushisa kwalesi sikhangiso kwenza kube kuhle kulo msebenzi. Ingamelana nama-500 ° C. Ukumelana kwayo okuphezulu kwenza kulungele izinhlelo ezahlukahlukene ezibucayi.

Izinamathiseli zePolyester

Lezi zinamatheli zisindisa kakhulu izindleko kunezinamathela e-polymide.

Bahle ngokwenza imibuthano eyisisekelo yokuqhuma iqhuma izifunda.

Ubudlelwano babo bubuthakathaka futhi. Adfives polyester nawo akuwona ukumelana nokushisa. Bavuselelwe muva nje. Lokhu kubanikeza ukumelana nokushisa. Lolu shintsho luphinde lukhuthaze ukuguqulwa. Lokhu kubenza baphephe emhlanganweni we-PCB we-Multilayer.

Adhesives acrylic

Lezi zinamathelayo ziphakeme. Banokuqina okuhle kakhulu okushisayo ngokumelene nokugqwala namakhemikhali. Kulula ukufaka isicelo futhi akubizi kakhulu. Kuhlanganiswe nokutholakala kwabo, badumile phakathi kwabakhiqizi. abakhiqizi.

Ama-epoxies

Lokhu mhlawumbe kungukunamathela okusetshenziswa kakhulu ekukhiqizweni komjikelezo okuqinile. Futhi bangamelana nokugqwala kanye namazinga okushisa aphezulu aphansi.

Futhi zivumelana kakhulu futhi zizinzile. Ine-polyester encane kuyo eyenza iguquke kakhulu.

Stack-up

Isitaki-sip se-PCB eqinile-ex kungenye yezitho eziningi ngesikhathi

Ukuqanjwa kwe-PCB eqinile futhi kuyinkimbinkimbi ngokwejwayelekile

Amabhodi aqinile, ake sibheke izingqimba ezi-4 ze-PCB eqinile njengoba ngezansi:

Imaski ephezulu ye-soler

Ungqimba oluphezulu

Dielectric 1

Ungqimba lwesiginali 1

Dielectric 3

Ungqimba lwesiginali 2

Dielectric 2

Ungqimba olungezansi

Ezansi soldermask

Umthamo we-PCB

| Umthamo webhodi eliqinile | |

| Inani lezendlalelo: | 1-42 izingqimba |

| Okubonakalayo: | I-FR4 \ ephezulu TG FR4 \ EHOLD Indwangu yamahhala \ CEM1 \ CEM3 \ Aluminium \ Metal |

| Ugqinsi ungqimba nzima: | 1-6oz |

| Ubukhulu obungaphakathi obuseceleni | 1-4OZ |

| Indawo ephezulu yokucubungula: | I-610 * 1100mm |

| Ubukhulu bebhodi elincane: | Izingqimba ezi-2 0.3mm (12mil) Izendlalelo ezi-4 0.4mm (16mil)6 Izabelo 0.8mm (32mil) Izingqimba eziyi-8 1.0mm (40mil) Izendlalelo eziyi-10 1.1mm (44mil) Izendlalelo eziyi-12 1.3mm (52mil) Izendlalelo eziyi-14 1.5mm (59mil) Izendlalelo eziyi-16 1.6mm (63mil) |

| Ububanzi obuncane: | 0.076mm (3mil) |

| Isikhala esincane: | 0.076mm (3mil) |

| Ubukhulu obuncane bemigodi (umgodi wokugcina): | 0.2mm |

| Isilinganiso se-Aspect: | 10: 1 |

| Usayizi we-Drilling Hole: | 0.2-0.65mm |

| Ukubekezelela Ukubamba: | + \ - 0.05mm (2mil) |

| Ukubekezelelana kwe-Pth: | Φ0.2-1.6mm + \ - 0.075mm (3mil) Φ1.6-6.3mm + \ - 0.1MM (4mil) |

| Ukubekezelelana kwe-NPTH: | Φ0.2-1.6mm + \ - 0.05mm (2mil) Φ1.6-6.3MM + \ - 0.05mm (2mil) |

| Qeda ukubekezelela ibhodi: | Ubukhulu <0.8mm, ukubekezelela: +/- 0.08mm |

| 0.8mm≤hickness≤6.5mm, ukubekezelelana +/- 10% | |

| Ubuncane be-soldermask bridge: | 0.076mm (3mil) |

| Ukusonteka nokugoba: | ≤0.75% min0.5% |

| I-RANEG ye-TG: | 130-215 ℃ |

| Ukubekezelelana kwe-Impodence: | +/- 10%, Min +/- 5% |

| Ukwelashwa okungaphezulu: | I-Hasl, lf hasl |

| Ukucwiliswa igolide, i-flash igolide, umunwe wegolide | |

| Isiliva yokucwilisa, i-tinsion tin, esp | |

| Ukukhetha igolide Plating, ubukhulu begolide kuze kufike ku-3um (120u ") | |

| I-Carbon Phrinta, i-S / m, eneepig | |

| Umthamo webhodi ye-aluminium | |

| Inani lezendlalelo: | Ungqimba olulodwa, izingqimba eziphindwe kabili |

| Ubukhulu bebhodi eliphakeme: | 1500 * 600mm |

| Ubukhulu bebhodi: | 0.5-3.0mm |

| Ubukhulu be-Copper: | 0.5-4OZ |

| Ubuncane be-Hole usayizi: | 0.8mm |

| Ububanzi obuncane: | I-0.1MM |

| Isikhala esincane: | I-0.12mm |

| Ubukhulu be-PAD obuncane: | I-10 micron |

| Qeda phezulu: | I-Hasl, Osp, Enig |

| Ukubumba: | CNC, punching, v-cut |

| Ukuhlinzekwa: | Umhloli we-Universal |

| Flying Probe evulekile / Umhloli Omfushane | |

| I-scross ephakeme ephezulu | |

| I-Solderability Testing Kit | |

| Umhloli wamandla we-peel | |

| I-High Volt evulekile & umhloli omfushane | |

| Isiphambano sesigaba sokubumba ikhithi nge-polisher | |

| Umthamo we-FPC | |

| Izendlalelo: | 1-8 izingqimba |

| Ubukhulu bebhodi: | 0.05-0.5mm |

| Ubukhulu be-Copper: | 0.5-3OZ |

| Ububanzi obuncane: | 0.075mm |

| Isikhala esincane: | 0.075mm |

| Ngosayizi we-hole: | 0.2mm |

| Ubuncane be-Laser Hole usayizi: | 0.075mm |

| Ubuncane be-thching hole usayizi: | I-0.5mm |

| Ukubekezelela kwe-soldermask: | + \ - 0.5mm |

| Ukubekezelelwa kwesilinganiso esiphansi: | + \ - 0.5mm |

| Qeda phezulu: | I-hasl, i-hasl ye-lf, isiliva yokucwilisa, igolide yokucwilisa, i-flash igolide, i-asp |

| Ukubumba: | Ukubhoboza, i-laser, ukusika |

| Ukuhlinzekwa: | Umhloli we-Universal |

| Flying Probe evulekile / Umhloli Omfushane | |

| I-scross ephakeme ephezulu | |

| I-Solderability Testing Kit | |

| Umhloli wamandla we-peel | |

| I-High Volt evulekile & umhloli omfushane | |

| Isiphambano sesigaba sokubumba ikhithi nge-polisher | |

| Qondisa futhi i-Flex umthamo | |

| Izendlalelo: | 1-28 izingqimba |

| Uhlobo lwezinto ezibonakalayo: | I-FR-4 (ephezulu ye-TG, i-halogen yamahhala, imvamisa ephezulu) PTFE, BT, GetEK, Aluminium Base, Copper Base, KB, KB, KB, ITEQ, Isola, Nelco, Roger, Arlon |

| Ubukhulu bebhodi: | I-6-240mil / 0.15-6.0mm |

| Ubukhulu be-Copper: | 210Um (6oz) ngesendlalelo sangaphakathi 210Um (6oz) ngesendlalelo sangaphandle |

| Min Mechanical Drill Usayizi: | 0.2mm / 0.08 " |

| Isilinganiso se-Aspect: | 2: 1 |

| Usayizi we-Max Panel: | Sigle Side noma Izinhlangothi Ezimbili: I-500mm * 1200mm |

| Izendlalelo ze-Multilayer: 508MM x 610mm (20 "x 24") | |

| Ububanzi / Isikhala se-Min: | 0.076mm / 0.076mm (0.003 "/ 0.003") / 3mil / 3mil |

| Uhlobo lweHole: | Impumputhe / Ukungcwatshwa / okuxhunyiwe (VOP, VIP ...) |

| HDI / Microvia: | Yebo |

| Qeda phezulu: | I-Hasl, lf hasl |

| Ukucwiliswa igolide, i-flash igolide, umunwe wegolide | |

| Isiliva yokucwilisa, i-tinsion tin, esp | |

| Ukukhetha igolide Plating, ubukhulu begolide kuze kufike ku-3um (120u ") | |

| I-Carbon Phrinta, i-S / m, eneepig | |

| Ukubumba: | CNC, punching, v-cut |

| Ukuhlinzekwa: | Umhloli we-Universal |

| Flying Probe evulekile / Umhloli Omfushane | |

| I-scross ephakeme ephezulu | |

| I-Solderability Testing Kit | |

| Umhloli wamandla we-peel | |

| I-High Volt evulekile & umhloli omfushane | |

| Isiphambano sesigaba sokubumba ikhithi nge-polisher | |