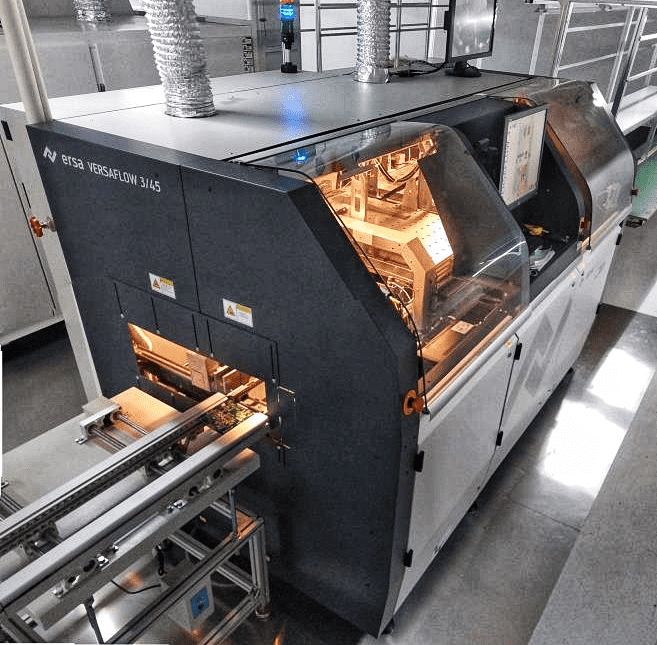

Enqubweni yokusoda ye-PCBA, ukusoda kwezingxenye ze-plug-in ku-PCBA ngokuvamile kuhilela ukuhlanganisa ngesandla noma ukunamathisela okuzenzakalelayo kwe-wave soldering, okubandakanya ukugwema izinto ezibekwe phezulu ze-SMT kanye nezimbobo ezithile ezingafakwanga ithayela, ezidinga ukwenziwa ngendlela oyifisayo izinto zokudayiswa.Lokhu kuphumela ezindlekweni ezengeziwe zokulungisa izinto, ukwanda kokusetshenziswa kwe-solder ngenxa yokwanda kwendawo engaphezulu kukathayela, ukusetshenziswa kakhulu kwamandla, kanye nokungcola okuphawulekayo.Ikakhulukazi ekubhekaneni nezinselele zokukhiqiza ama-batches amancane ngemikhiqizo ehlukahlukene, isikhathi esidingekayo sokwakhiwa kwempahla kunzima ukuhlangabezana nayo.Ukuze kufezwe kangcono izibopho zokusebenza kahle nekhwalithi, ikakhulukazi ekuhlangabezaneni nezidingo zokushisela zemikhiqizo esezingeni eliphezulu ezimbonini ezifana nezezimoto, ezondiza, i-aerospace, nezempi, i-ANKE PCB isanda kwethula ubuchwepheshe obusezingeni eliphezulu kakhulu bokukhetha amagagasi emhlabeni. , umshini okhethiwe we-wave soldering owenziwe yi-ERSA VERSAFLOW 3/45 owenziwe eJalimane.Lo mshini udambisa futhi unciphisa izinkinga ezishiwo ngenhla, uthuthukisa ukusebenza kahle kokucubungula, ukwethembeka kwekhwalithi, nokuzinza kwemikhiqizo edayisiwe.

Uma kuqhathaniswa ne-wave soldering yendabuko, lesi sisetshenziswa sinezici ezilandelayo ezithuthukile:

● Ukuzijwayeza okuzenzakalelayo ku-PCB

Ngaphansi kokuxhumana kwesistimu ye-MES, ingabiza ngokuzenzakalelayo uhlelo lokushisela ngokusebenzisa ukuqashelwa kwekhodi ye-QR kumabhodi e-PCB ahlukene, futhi izuze ukushintsha okusheshayo ku-inthanethi;

● Ikhwalithi ethembeke kakhudlwana

I-ERSA selective wave soldering ihlinzeka ngekhwalithi enhle yokushisela - ukuzinza komkhiqizo kanye nezinga lokuthembeka kungafinyelela ku-99.999%.Ibiza ngokuzenzakalelayo uhlelo lwe-welding olusethiwe ukuze kuzuzwe ukulungiswa kwe-inthanethi kwesikhathi se-welding kanye nevolumu ye-solder ngokuya ngezidingo zokushisela zezingxenye ezahlukene.Lokhu kuqeda ukushisa okweqile kwedivayisi noma ukushisa ngaphansi futhi kuqinisekisa ukuthi akukho bhuloho le-solder noma i-voids, okuholela emajoyini e-solder abukeka kahle.

● Yehlisa ukusetshenziswa kwe-solder

I-wave soldering evamile idinga i-solder engaphezulu kuka-400KG, futhi i-solder idinga ukuncibilika ngokuqhubekayo futhi inyakaze, okuholela ku-1KG/H yemfucumfucu ye-solder.Ngokuphambene, i-ERSA idinga kuphela inani le-solder lika-10KG okugeza ngakunye, ikhiqiza kuphela u-2KG we-solder dross ngenyanga.Ngesikhathi se-soldering, i-solder iron iron ivikelwe yigesi ye-nitrogen engu-99.999%, iqinisekisa ukuthi i-100% ye-solder isetshenziselwa amalunga e-solder futhi inciphisa ukukhiqizwa kwe-solder dross.Lesi sici asiqinisekisi nje kuphela ukuhlanzeka kwendawo ye-solder kodwa futhi sithuthukisa kakhulu ikhwalithi ye-solder futhi sinciphisa kakhulu ukusetshenziswa kwe-solder.

● Ukonga ugesi kanye nemvelo

I-ERSA selective wave soldering iwonga amandla - ukusetshenziswa kwamandla kungu-12KW kuphela, okuyi-1/4 ye-wave soldering evamile.I-ERSA selective wave soldering iqeda isidingo sokulungiswa okukhethekile okuthatha isikhathi kanye nezindleko zokukhiqiza inqwaba ye-wave soldering evamile.Ukugeza okushisisa nge-solder okuphakathi nendawo kanye nokushisa kwangaphambi kwesikhathi okuzenzakalelayo kunciphisa ukusetshenziswa kwamandla cishe ngo-25%.Iphuzu elizenzakalelayo lokufafaza indlela yamajoyinti e-solder kunciphisa kakhulu ukusetshenziswa kwezinto eziguquguqukayo ezingavumelani nemvelo cishe ngo-80% futhi kunciphisa kakhulu ukungcola okuvela ezinsalela zamakhemikhali ezikhiqizwa phakathi nenqubo yokuhlanza ye-PCB yakamuva cishe ngama-70%.

Ngemva kokwethulwa nokusetshenziswa kwesistimu yokudayiswa kwamagagasi ekhethiwe ye-ERSA yaseJalimane, izinga lekhwalithi elihlanganyelwe le-solder yokuqala lezingxenye ze-plug-in ze-ANKE PCB (ezifana nezixhumi, amabhulokhi wetheminali, njll.) linyuke lisuka ku-91.3% laya ku-99.9%.Lokhu kuye kwabhekana kakhulu nezingozi zekhwalithi kanye nezingozi ezingase zibe khona kule nqubo ebucayi, ukunikeza isiqinisekiso esiqinile nesanele sokuthembeka kwe-solder nokuzinza kwemikhiqizo ephezulu yamakhasimende.Kwenza kube lula ukuguqulwa okusheshayo kocwaningo kanye nezimpumelelo zentuthuko zibe yizimpahla ezidayiswayo futhi kugunyaze ukuthuthukiswa okusimeme kwemikhiqizo.

I-Shenzhen ANKE PCB Co., LTD

2023-8-22

Isikhathi sokuthumela: Aug-23-2023