Ukwenza ukuxazulula inkinga nokulungiswa kuyoAma-PCBkunganwebeka isikhathi sokuphila sempilo. Uma i-PCB enephutha ihlangana phakathi kweI-PCB AssemblyInqubo, ibhodi le-PCB lingalungiswa ngokususelwa kuhlobo lokungasebenzi kahle. Ngezansi kwezinye izindlela zokuxazulula inkinga nokulungisa ama-PCB.

1. Ukwenza kanjani ukulawulwa kwekhwalithi ku-PCB ngesikhathiInqubo Yokukhiqiza?

Imvamisa, amafektri we-PCB anemishini ekhethekile nezinqubo ezibalulekile ezinika amandla ukulawulwa kwekhwalithi kwama-PCB kuyo yonke inqubo yokukhiqiza.

Ukuhlolwa kwe-AOI kuskena ngokuzenzakalelayo izingxenye ezingekho, ukungaphatheki kahle kwengxenye, nezinye iziphambeko ku-PCB. Izinsizakusebenza ze-AOI zisebenzisa amakhamera ukuthwebula izithombe eziningi ze-PCB futhi ziziqhathanisa namabhodi ereferensi. Lapho i-mismatch itholwa, ingakhombisa amaphutha okungenzeka.

1.2. Ukuhlolwa kwe-Flying Probe

Ukuhlolwa kweFlying Probe kusetshenziselwa ukukhomba amasekethe amafushane futhi avulekile, izingxenye ezingalungile (ama-diodes kanye nama-transistors), kanye namaphutha ekuvikelweni kwe-diode. Izindlela ezahlukahlukene zokulungisa ama-PCB zingasetshenziswa ukulungisa ama-shorts namaphutha engxenye.

I-FCT (ukuhlolwa okusebenzayo) igxile ekuhlolweni okusebenzayo kwama-PCB. Amapharamitha wokuhlola ngokuvamile anikezwa onjiniyela futhi angafaka izivivinyo ezilula zokushintsha. Kwezinye izimo, isoftware ekhethekile nezinqubomgomo eziqondile zingadingeka. Ukuhlolwa okusebenzayo kuhlola ngokuqondile ukusebenza kwe-PCB ngaphansi kwezimo zangempela zezemvelo.

2. Izimbangela ezijwayelekile zomonakalo we-PCB

Ukuqonda izimbangela ze-PCB ukwehluleka kungakusiza ekuboneni masinyane amaphutha we-PCB. Nawa amanye amaphutha ajwayelekile:

Ukwehluleka kwengxenye: Ukungena esikhundleni izingxenye ezingonakele kungavumela umjikelezo ukuthi asebenze kahle.

Ukushisa ngokweqile: Ngaphandle kokuphathwa kahle kokushisa, ezinye izinto zingashiswa.

Ukulimala ngokomzimba: Lokhu kudalwa ikakhulukazi ukuphathwa kabi,

Ukuholela emifungolweni ezingxenyeni, amajoyinti we-solder, izingqimba zemithambo ye-solder mask, iminonjana, kanye namaphampu.

Ukonakalisa: Uma i-PCB ivezwa izimo ezinzima, iminonjana nezinye izinto zethusi zingalungiswa.

3. Ungaxazulula Kanjani Amaphutha we-PCB?

Ukulandela izinhlu ziyizindlela eziyi-8:

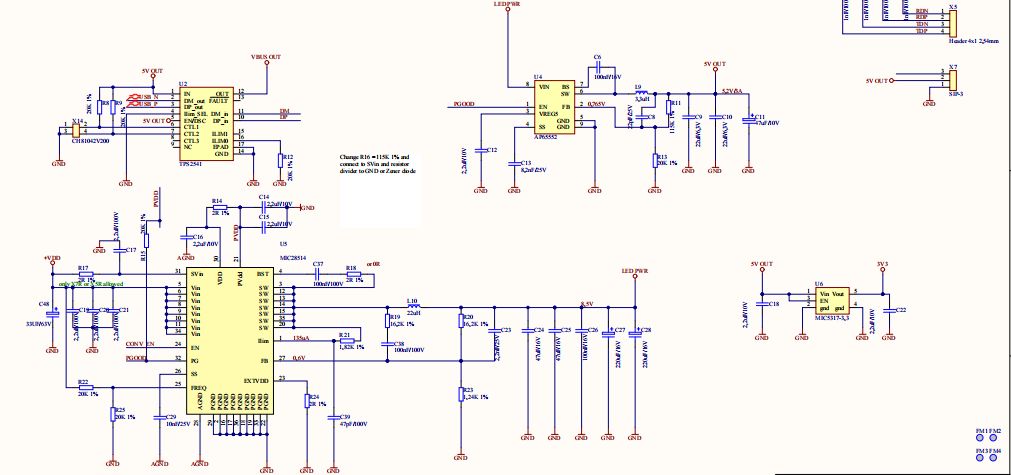

3-1. Qonda uSusematisi Wesekethe

Kunezinto eziningi kwi-PCB, ezixhumene neminonjana yethusi. Kubandakanya ukunikezwa kwamandla, umhlabathi, kanye namasiginali ahlukahlukene. Ngaphezu kwalokho, kunemibuthano eminingi, njengokuhlunga, ama-capacitors aqothulayo, kanye ne-inductors. Ukuqonda lokhu kubalulekile ukulungiswa kwe-PCB.

Ukwazi ukuthi ungayilandelela kanjani indlela yamanje futhi uhlukanise izigaba ezingenaphutha ezithembele ekuqondeniIsikimu Sesekeli. Uma i-schematic ingatholakali, kungahle kudingeke ukubuyisela emuva unjiniyela osuselwa ku-PCB Layout.

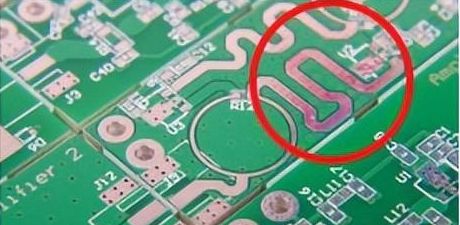

3-2. Ukuhlolwa Okubonakalayo

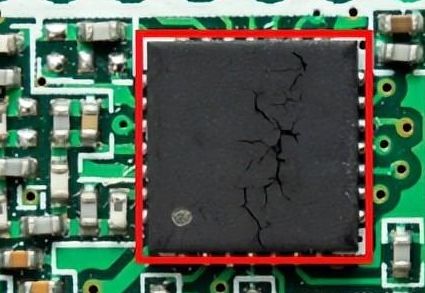

Njengoba kushiwo ngaphambili, ukushisa ngokweqile kungenye yezimbangela eziphambili zamaphutha we-PCB. Noma yiziphi izingxenye ezishisiwe, ukulandelana, noma amajoyinti we-solder angabonakala kalula lapho kungekho kokufakwa kwamandla. Ezinye izibonelo zezinkinga zifaka:

- Ukubhidliza / Ukugqagqana / Izakhi ezingekho

- Ukulandela iminwe

- Amajoyina wokugcina abandayo

- umthengisi ngokweqile

- Izingxenye ezinezitebhisi

- Amaphakethe aphakanyisiwe / alahlekile

- Imifantu ku-PCB

Konke lokhu kungabonakala ngokuhlola okubukwayo.

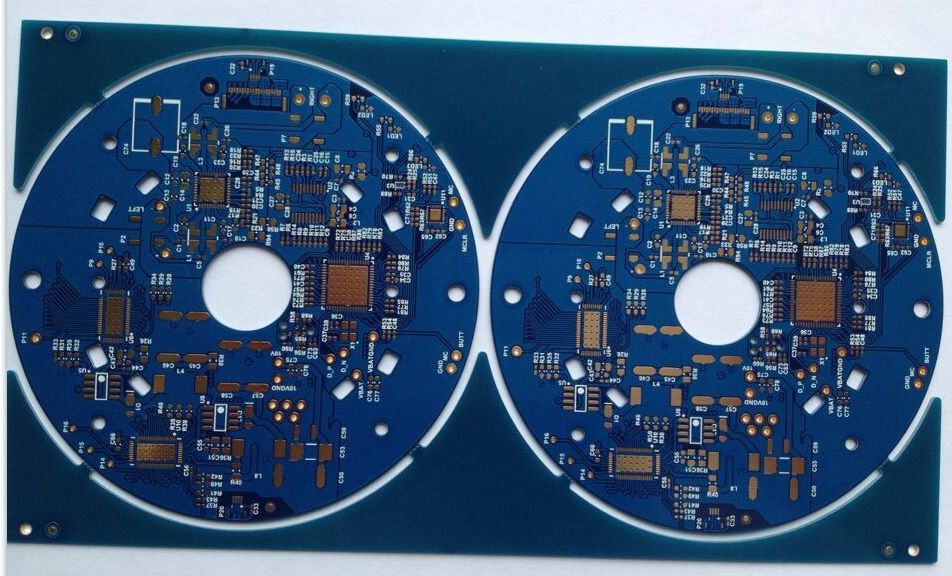

3-3. Qhathanisa ne-PCB efanayo

Uma unenye i-PCB efanayo ngokusebenza okukodwa kahle nakwelinye iphutha, kuba lula kakhulu. Ungabhekabheka ngokwezifiso, ukuphathwa kabi, kanye namaphutha ekulandelweni noma ku-vias. Ngokwengeziwe, ungasebenzisa i-multimeter ukubheka ukufakwa kokufaka nokukhishwa kwawo womabili amabhodi. Amanani afanayo kufanele atholakale kusukela ama-PC amabili afanayo.

3-4. HLOLA IZIMPAWU ZOKUGCINA

Lapho ukuhlolwa okubukwayo kunganele, ungathembela kumathuluzi afana ne-multimeter nomaAmamitha ayi-LCR. Hlola isakhi ngasinye ngokusekelwe kuma-datasheets nezidingo zokuklama. Izibonelo zibandakanya abashumayezi, ama-capacitors, ama-inducrosour, ama-diodes, ama-trafistors kanye nama-LED.

Isibonelo, ungasebenzisa ukuhlelwa kwe-dide ku-multimeter ukuhlola ama-diode kanye nama-transistors. I-Base-Collector kanye ne-Base-Emitter lungiction act njenge-diodes. Ngemiklamo yebhodi elula yesekethe, ungabheka amasekethe avulekile futhi amafushane kukho konke ukuxhumana. Mane nje usethe imitha ukumelana noma imodi yokuqhubeka futhi uqhubeke nokuhlola ukuxhumana ngakunye.

Lapho uqhuba amasheke, uma ukufundwa kungaphakathi kokucaciswa, ingxenye ibhekwa njengesebenza kahle. Uma ukufundwa kungajwayelekile noma kuphakeme kunalokho obekulindelwe, kungahle kube nezinkinga ezinengxenye noma amalunga we-solder. Ukuqonda i-voltage elindelekile kumaphoyinti wokuhlola kungasiza ekuhlaziyweni kwesekethe.

Enye indlela yokuhlola izingxenye ngokuhlaziywa kwe-nodal. Le ndlela ifaka ukusebenzisa i-voltage ezingxenyeni ezikhethiwe ngenkathi ingasebenzi kahle isifunda kanye nokulinganisa izimpendulo ze-voltage (V-Repred). Khomba zonke izinombolo bese ukhetha ireferensi exhunywe kwizakhi ezibalulekile noma imithombo yamandla. Sebenzisa umthetho wamanje weKirchhoff (KCL) ukubala ama-voltages angaziwa ne-node (okuguquguqukayo) bese uqinisekisa uma lawa manani ahambelana nalawo alindelwe. Uma kunezingqinamba ezibonwe endaweni ethile, kukhombisa iphutha kuleyo node.

3-5.Ukuhlola amasekethe ahlanganisiwe

Ukuhlola amasekethe ahlanganisiwe kungaba ngumsebenzi omkhulu ngenxa yobunzima babo. Nazi ezinye izivivinyo ezingenziwa:

- Khomba konke ukubekwa bese uvivinya i-IC usebenzisa i-Logic Analyzer nomaI-Oscilloscope.

- Bheka ukuthi i-IC iqondiswe kahle yini.

- Qinisekisa ukuthi wonke amalunga womthengisi axhunywe kwi-IC asesimweni esihle sokusebenza.

- Hlola isimo sanoma yikuphi ukushushuluza okushisayo noma amaphaphu we-thermal axhumeke kwi-IC ukuqinisekisa ukufethina okushisa okulungile.

3-6. Ukuhlola ukunikezwa kwamandla

Ukuxazulula inkinga yezinkinga zokunikezwa kwamandla, kuyadingeka ukukala ama-voltages wesitimela. Ukufundwa nge-voltmeter kungabonisa amanani wokufaka kanye nokuphuma kwezinto. Izinguquko ezikugesi zingakhombisa izinkinga zesifunda ezingaba khona. Isibonelo, ukufundwa kwe-0V esitimeleni kungakhombisa umjikelezo omfushane ekunikezelweni kwamandla, okuholela ekuthini kwethonya. Ngokwenza izivivinyo zobuqotho bamandla futhi uqhathanisa amanani alindelwe ezilinganisweni zangempela, izinto eziphikisayo zamandla zingahlukaniswa.

3-7. Ukuhlonza ama-hotspots ejikeleza

Lapho amaphutha abukwayo awatholakali, ukuhlolwa komzimba ngokusebenzisa umjovo wamandla kungasetshenziswa ukuhlola umjikelezo. Ukuxhumeka okungalungile kungakhiqiza ukushisa, okungazwakala ngokubeka isandla ebhodini lesekethe. Enye inketho ukusebenzisa ikhamera yokucabanga eshisayo, evame ukuthandwa yimibuthano ephansi yamandla. Izindlela zokuphepha zokuphepha kufanele zithathwe ukugwema izingozi zikagesi.

Enye indlela ukuqinisekisa ukuthi usebenzisa isandla esisodwa kuphela sokuhlola. Uma indawo eshisayo itholwa, idinga ukwehliswa phansi, bese wonke amaphuzu okuxhuma kufanele ahlolwe ukuthola ukuthi inkinga ilele kuphi.

3-8. Ukuxazulula inkinga ngamasu wokuhlola amasinali

Ukuze usebenzise le ndlela, kubalulekile ukuba nokuqonda amanani alindelekile nama-waveforms ezindaweni zokuhlola. Ukuhlolwa kwamandla kagesi kungenziwa ngamaphuzu ahlukahlukene usebenzisa i-multimeter, oscilloscope, noma noma iyiphi insiza yokuthatha indawo ye-waveform. Ukuhlaziya imiphumela kungasiza emaphutheni ahlukanisayo.

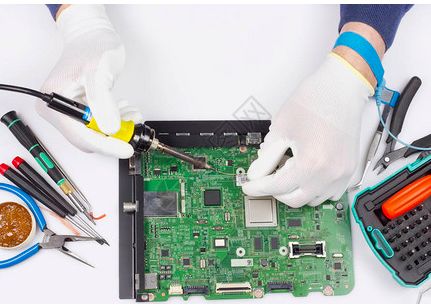

4. Amathuluzi adingekayoUkulungiswa kwe-PCB

Ngaphambi kokwenza noma yikuphi ukulungiswa, kubalulekile ukuqoqa amathuluzi adingekayo omsebenzi, njengoba isisho sihamba, 'ummese ocijile ngeke asike izinkuni.'

● Isikhungo esisetshenziselwa ukufakwa kwe-ESD, izisekelo zamandla, nokukhanya kubalulekile.

● Ukunciphisa ukushaqeka okushisayo, ama-heater afrared noma ama-deseaters angahle acelwe ukuze aqale phansi ibhodi yesekethe.

● Kudingeka uhlelo lokufaka okunembile ngokushaywa kanye nokuvula umgodi ngesikhathi senqubo yokulungisa. Lolu hlelo luvumela ukulawula ububanzi nokujula kwama-slots.

● Insimbi enhle yokuthengisa iyadingeka ukuze i-soldering ukuqinisekisa amajoyinti afanele wollo.

● Ngaphezu kwalokho, i-electroplating nayo ingadingeka.

● Uma ungqimba lwe-mask MASD lulimele, kuzodinga ukulungiswa. Ezimweni ezinjalo, ungqimba lwe-epoxy resin luncono.

I-5. Izinyathelo zokuphepha ngesikhathi sokulungiswa kwe-PCB

Kubalulekile ukuthatha izindlela zokuvimbela ukugwema izingozi zokuphepha ngesikhathi senqubo yokulungisa.

● Imishini yokuvikela: Lapho ubhekene namazinga okushisa aphezulu noma amandla aphezulu, ukugqoka imishini yokuvikela kumele. Izibuko zokuphepha namagilavu kufanele agqoke ngezinqubo zokuthengisa kanye nokumba, ukuvikela ezingozini zamakhemikhali angaba khona.

Egqoke amagilavu ngenkathi ilungisa ama-PCB.

● Ukukhishwa kwe-ElectrostSATIC (ESD): Ukuvimbela ukushaqeka kukagesi okubangelwa yi-ESD, qiniseka ukuthi ukhipha umthombo wamandla nokukhipha noma yimuphi ugesi osalayo. Ungase futhi ugqoke izihlakala eziphansi noma usebenzise ama-anti-static mat ukuze uphinde unciphise ubungozi be-ESD.

6. Ukulungisa kanjani i-PCB?

Amaphutha ajwayelekile kwi-PCB avame ukufaka iziphambeko ekulandelweni, ezingxenyeni, kanye nama-plaps we-solder.

6-1. Ukulungisa iminwe elonakalisiwe

Ukulungisa umkhondo ophukile noma olimele kwi-PCB, sebenzisa into ebukhali ukuze udalule indawo engaphezulu yokulandela umkhondo woqobo bese ususa imaskhi yomthengisi. Hlanza indawo yethusi nge-solvent ukususa noma iyiphi imfucumfucu, isiza ukufeza ukuqhubeka kukagesi okungcono.

Ngenye indlela, ungathengisa izintambo ze-jumper ukulungisa iminonjana. Qinisekisa ukuthi ububanzi bentambo buhambisana nokulandela umkhondo ukuze uthole amandla afanele.

6-2.Ukubuyisela Izici Ezingalungile

Ukushintsha izingxenye ezilimele

Ukususa izakhi ezinephutha noma umthengisi ngokweqile kusuka kumajoyinti we-solder, kuyadingeka ukuncibilika umthengisi, kepha kufanele kuthathwe ukuqaphela ukugwema ukukhiqiza ukucindezela okushisayo endaweni ezungezile. Ukulandela izinyathelo ezingezansi ukuze ungene esikhundleni sezakhi esifundeni:

● Shisisa amalunga womthengisi ngokushesha usebenzisa ithuluzi le-iron noma i-depoldering.

● Lapho umthengisi esencibilikisiwe, sebenzisa ipompo ebonakalayo ukuze ususe uketshezi.

● Ngemuva kokususa konke ukuxhumana, isakhi sizovinjelwa.

● Okulandelayo, Hlanganisa ingxenye entsha bese uyiphola endaweni.

● Nquma ubude obuningi bengxenye yesandla kuholela usebenzisa ama-wire cutter.

● Ukuqinisekisa ukuthi ama-terminals axhunyiwe ngokusho kwenhlangano edingekayo.

6-3. Ukulungisa ama-Pads alonakalisiwe we-solder

Ngokuhamba kwesikhathi kuqhubekela phambili, ama-pads we-soler ku-PCB angaphakamisa, i-Corpode, noma ikhefu. Nazi izindlela zokulungisa ama-solder pads alimele:

Aphakamisele pads we-sole: Hlanza indawo nge-solvent usebenzisa i-swab kakotini. Ukuhlanganisa i-pad emuva endaweni, faka i-resin ephangayo e-Pad Pad bese uyicindezela phansi, ivumela i-resin ye-epoxy ukuthi yelaphe ngaphambi kokuqhubeka nenqubo yokuthengisa.

Ama-pads owonakalisiwe noma angcolisiwe: Susa noma usike noma usike i-solder pad elonakalisiwe, ukudalula umkhondo oxhunyiwe ngokusula imaski yomthengisi ezungeze i-pad. Hlanza indawo nge-solvent usebenzisa i-swab kakotini. Ephepheni elisha le-soler (elixhunywe kulo mkhondo), faka ungqimba we-resin ye-epoxy ephethe futhi uyivikele endaweni. Okulandelayo, engeza i-epoxy resin phakathi komkhondo kanye ne-solder pad. Yilaphe ngaphambi kokuqhubeka nenqubo yokudambisa.

UShenzhen Angeke PCB Co, LTD

2023-7-20

Isikhathi sePosi: UJul-21-2023