Ukwenza ukuxazulula izinkinga nokulungisa kuma-PCB kunganweba isikhathi sempilo yamasekhethi.Uma i-PCB engalungile ihlangatshezwana nayo phakathi nenqubo yokuhlanganisa i-PCB, ibhodi le-PCB lingalungiswa ngokusekelwe kuhlobo lokungasebenzi kahle.Ngezansi kukhona ezinye izindlela zokuxazulula izinkinga nokulungisa ama-PCB.

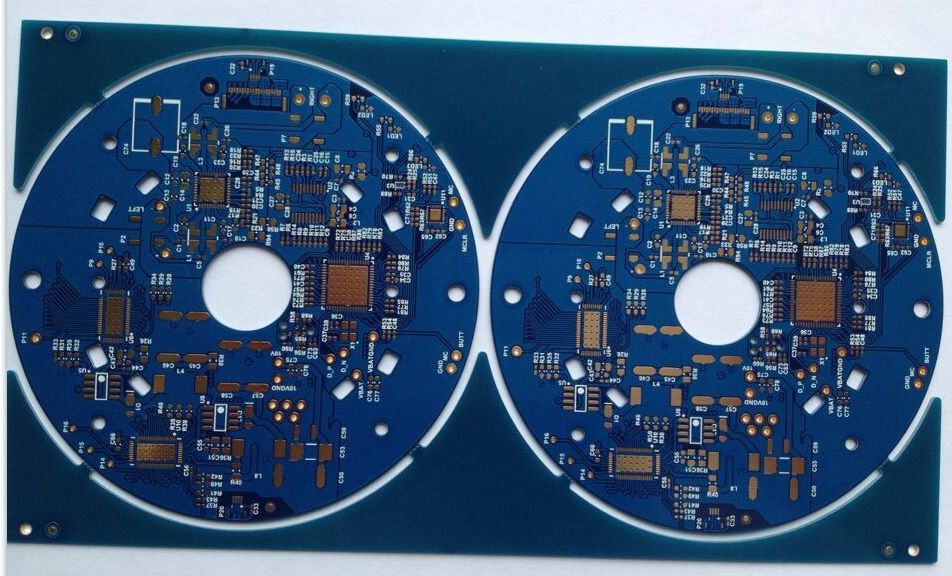

1. Kwenziwa kanjani ukulawula izinga ku-PCB phakathi nenqubo yokukhiqiza?

Ngokuvamile, izimboni ze-PCB zinemishini ekhethekile nezinqubo ezibalulekile ezivumela ukulawulwa kwekhwalithi yama-PCB kuyo yonke inqubo yokukhiqiza.

1.1.Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-AOI kuskena ngokuzenzakalela izingxenye ezingekho, izingxenye ezingafakwanga kahle, nokunye ukonakala ku-PCB.Izinto ze-AOI zisebenzisa amakhamera ukuze zithwebule izithombe eziningi ze-PCB futhi ziziqhathanise namabhodi ezithenjwa.Uma kutholwa ukungafani, kungabonisa amaphutha okungenzeka.

1.2.Ukuhlolwa kwe-Flying Probe

Ukuhlolwa kwe-Flying probe kusetshenziselwa ukukhomba amasekhethi amafushane navulekile, izingxenye ezingalungile (ama-diode nama-transistors), kanye nokukhubazeka ekuvikelweni kwe-diode.Izindlela ezahlukahlukene zokulungisa i-PCB zingasetshenziswa ukulungisa izikhindi namaphutha ezingxenye.

1.3.Ukuhlolwa kwe-FCT

I-FCT (Functional Test) igxile kakhulu ekuhlolweni kokusebenza kwama-PCB.Amapharamitha wokuhlola ngokuvamile ahlinzekwa onjiniyela futhi angafaka phakathi ukuhlolwa kokushintsha okulula.Kwezinye izimo, kungase kudingeke isofthiwe ekhethekile namaphrothokholi anembile.Ukuhlola okusebenzayo kuhlola ngokuqondile ukusebenza kwe-PCB ngaphansi kwezimo zemvelo zomhlaba wangempela.

2. Izimbangela Ezijwayelekile Zokulimala Kwe-PCB

Ukuqonda izimbangela zokuhluleka kwe-PCB kungakusiza ukuthi ubone ngokushesha amaphutha e-PCB.Nawa amaphutha avamile:

Ukwehluleka kwengxenye: Ukushintsha izingxenye ezingalungile kungavumela isifunda ukuthi sisebenze kahle.

Ukushisa ngokweqile: Ngaphandle kokuphathwa kahle kokushisa, ezinye izingxenye zingasha.

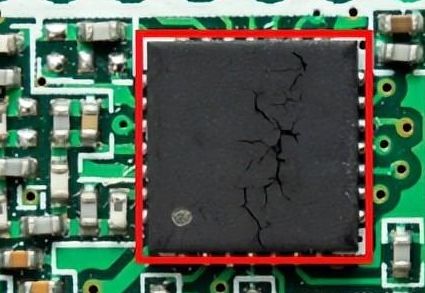

Ukulimala ngokomzimba: Lokhu kubangelwa ikakhulukazi ukuphatha kabi,

okuholela ekuqhekekeni kwezingxenye, amalunga e-solder, izendlalelo zemaski ye-solder, imikhondo, namaphedi.

Ukungcola: Uma i-PCB ibhekene nezimo ezinzima, imikhondo nezinye izingxenye zethusi zingagqwala.

3. Ungawaxazulula Kanjani Amaphutha e-PCB?

Uhlu olulandelayo luyizindlela eziyi-8:

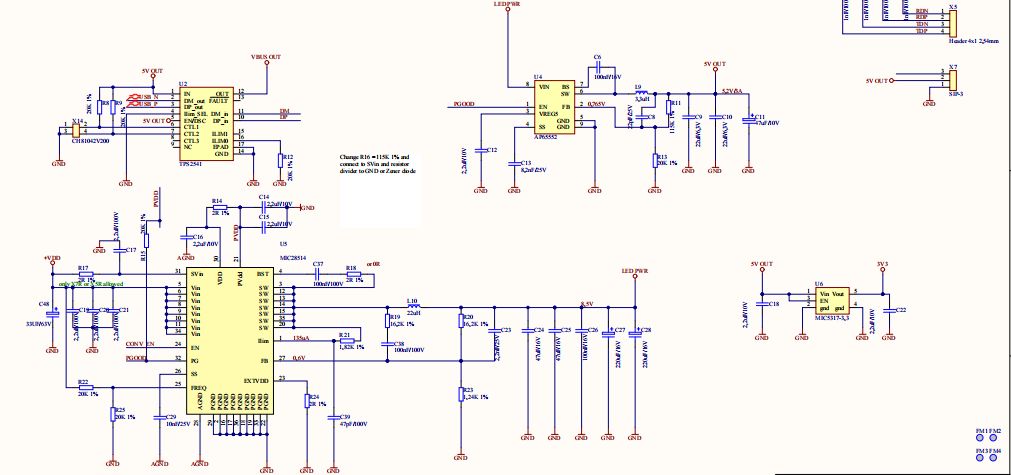

3-1.Qonda uhlelo lwesekethe

Kunezingxenye eziningi ku-PCB, ezixhunywe ngemikhondo yethusi.Kuhlanganisa ukunikezwa kwamandla, umhlabathi, namasignali ahlukahlukene.Ukwengeza, kunamasekhethi amaningi, njengezihlungi, ama-decoupling capacitor, nama-inductors.Ukuqonda lokhu kubalulekile ekulungiseni i-PCB.

Ukwazi ukulandelela indlela yamanje nokuhlukanisa izigaba ezinephutha kuncike ekuqondeni uhlelo lwesekethe.Uma ngabe i-schematic ingatholakali, kungase kudingeke ukubuyisela emuva unjiniyela wohlelo ngokusekelwe kusakhiwo se-PCB.

3-2.Ukuhlola Okubonakalayo

Njengoba kushiwo ngaphambili, ukushisa ngokweqile kungenye yezimbangela eziyinhloko zamaphutha e-PCB.Noma yiziphi izingxenye ezishile, imikhondo, noma amajoyinti e-solder angabonakala kalula uma kungekho okokufaka kwamandla.Ezinye izibonelo zokukhubazeka zihlanganisa:

- Izingxenye eziqhumayo/ezigqagqene/ezingekho

- Iminonjana eshintshe umbala

- Cold solder amalunga

- I-solder eyeqile

- Izingxenye zamatshe ethuna

- Amaphedi aphakanyisiwe/angekho

- Imifantu ku-PCB

Konke lokhu kungabonwa ngokuhlola okubonwayo.

3-3.Qhathanisa ne-PCB Efanayo

Uma unenye i-PCB efanayo esebenza kahle futhi enye inephutha, kuba lula kakhulu.Ungakwazi ukuqhathanisa izingxenye, ukungahambi kahle, kanye nokukhubazeka ngokulandela umkhondo noma nge-vias.Ukwengeza, ungasebenzisa i-multimeter ukuze uhlole okokufaka nokuphumayo kokufundwa kwawo womabili amabhodi.Amanani afanayo kufanele atholakale njengoba ama-PCB amabili afana.

3-4.Hlukanisa Izingxenye Ezinephutha

Uma ukuhlola okubukwayo kunganele, ungathembela kumathuluzi afana ne-multimeter noma imitha ye-LCR.Hlola ingxenye ngayinye ngokusekelwe kumininingwane yedatha kanye nezidingo zedizayini.Izibonelo zifaka ama-resistor, ama-capacitor, ama-inductors, ama-diode, ama-transistors, nama-LED.

Isibonelo, ungasebenzisa ukulungiselelwa kwe-diode ku-multimeter ukuhlola ama-diode nama-transistors.I-base-collector kanye ne-base-emitter junctions isebenza njengama-diode.Ukuze uthole imiklamo elula yebhodi lesifunda, ungabheka izifunda ezivulekile nezifushane kukho konke ukuxhumana.Mane usethe imitha kumodi yokumelana noma yokuqhubeka bese uqhubeke uhlola ukuxhumana ngakunye.

Lapho uhlola, uma ukufundwa kungaphakathi kokucaciswa, ingxenye ibhekwa njengesebenza kahle.Uma ukufundwa kungavamile noma kungaphezu kwalokho okulindelekile, kungase kube nezinkinga ngengxenye noma amajoyinti e-solder.Ukuqonda i-voltage elindelekile ezindaweni zokuhlola kungasiza ekuhlaziyeni isifunda.

Enye indlela yokuhlola izingxenye iwukuhlaziya i-nodal.Le ndlela ihilela ukusebenzisa i-voltage ezingxenyeni ezikhethiwe kuyilapho unganiki amandla isekethe yonke kanye nokukala izimpendulo ze-voltage (V-response).Khomba wonke ama-node bese ukhetha ireferensi exhunywe ezingxenyeni ezibalulekile noma imithombo yamandla.Sebenzisa Umthetho Wamanje we-Kirchhoff (KCL) ukuze ubale ama-voltage e-node angaziwa (okuguquguqukayo) futhi uqinisekise ukuthi la manani afana nalawo alindelekile.Uma kunezinkinga ezibonwa endaweni ethile, kukhombisa iphutha kuleyo nodi.

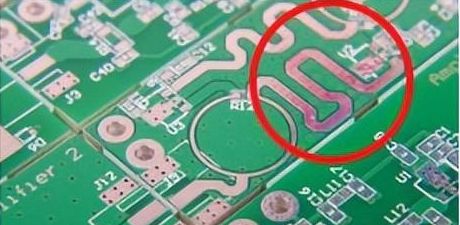

3-5.Ukuhlola Izifunda Ezididiyelwe

Ukuhlola amasekhethi ahlanganisiwe kungaba umsebenzi omkhulu ngenxa yobunkimbinkimbi bawo.Nazi ezinye izivivinyo ezingenziwa:

- Khomba zonke izimpawu bese uhlola i-IC usebenzisa i-logic analyzer noma i-oscilloscope.

- Hlola ukuthi i-IC iqondiswe kahle yini.

- Qinisekisa ukuthi wonke amajoyinti e-solder axhunywe ku-IC asesimweni esihle sokusebenza.

- Hlola isimo sanoma yimaphi amasinki okushisa noma amaphedi ashisayo axhunywe ku-IC ukuze uqinisekise ukulahlwa kokushisa okufanele.

3-6.Ukunikezwa kwamandla okuhlola

Ukuze uxazulule izinkinga zokuphakelwa kukagesi, kuyadingeka ukukala ama-voltage kaloliwe.Ukufundwa kwe-voltmeter kungabonisa amanani okufakwayo nokuphumayo kwezingxenye.Izinguquko ku-voltage zingakhombisa izinkinga ezingaba khona zesekethe.Isibonelo, ukufundwa kwe-0V kumzila wesitimela kungase kubonise isifunda esifushane kugesi, okuholela ekushiseni okweqile kwengxenye.Ngokwenza izivivinyo zobuqotho bamandla nokuqhathanisa amanani alindelekile nezilinganiso zangempela, ukunikezwa kwamandla okuyinkinga kungahlukaniswa.

3-7.Ukuhlonza Izindawo Ezishisayo Zesifunda

Uma ukukhubazeka okubukwayo kungatholakali, ukuhlola ngokomzimba ngomjovo wamandla kungasetshenziswa ukuhlola isekethe.Ukuxhumana okungalungile kungadala ukushisa, okungazwakala ngokubeka isandla ebhodini lesifunda.Enye inketho ukusebenzisa ikhamera yokuthwebula eshisayo, evame ukukhethwa kumasekhethi ane-voltage ephansi.Izinyathelo zokuphepha ezidingekayo kufanele zithathwe ukuze kugwenywe izingozi zikagesi.

Enye indlela ukuqinisekisa ukuthi usebenzisa isandla esisodwa kuphela ukuhlola.Uma kutholwa indawo eshisayo, idinga ukwehliswa, bese zonke izindawo zokuxhuma kufanele zihlolwe ukuze kutholwe ukuthi inkinga ilele kuphi.

3-8.Ukuxazulula inkinga ngamasu okuhlola amasignali

Ukusebenzisa le nqubo, kubalulekile ukuqonda amanani alindelekile nama-waveform ezindaweni zokuhlola.Ukuhlolwa kwe-voltage kungenziwa ezindaweni ezihlukahlukene kusetshenziswa i-multimeter, i-oscilloscope, nanoma iyiphi idivayisi yokuthwebula i-waveform.Ukuhlaziya imiphumela kungasiza ekuhlukaniseni amaphutha.

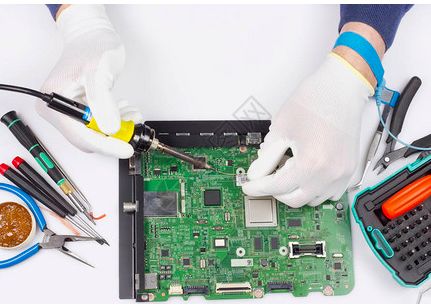

4. Amathuluzi Adingekayo Wokulungisa I-PCB

Ngaphambi kokwenza noma yikuphi ukulungisa, kubalulekile ukuqoqa amathuluzi adingekayo alo msebenzi, njengoba kusho isisho esithi, 'Ummese obuthuntu ngeke ugawule izinkuni.'

● Ithebula lokusebenza elinesisekelo se-ESD, amasokhethi kagesi, nokukhanyisa kubalulekile.

● Ukunciphisa ukushaqeka kwe-thermal, izifudumezi ze-infrared noma izifudumezi zangaphambili zingadingeka ukuze kushise kuqala ibhodi lesekhethi.

● Isistimu yokumba enembile iyadingeka ukuze kufakwe imbobo nokuvuleka kwemigodi ngesikhathi sokulungisa.Lolu hlelo luvumela ukulawula ububanzi nokujula kwezikhala.

● Kudingeka i-ayina ekahle yokudambisa ukuze kuqinisekiswe amajoyinti afanele.

● Ngaphezu kwalokho, kungase kudingeke i-electroplating.

● Uma isendlalelo semaski ye-solder sonakalisiwe, sizodinga ukulungiswa.Ezimweni ezinjalo, ungqimba lwe-epoxy resin lungcono.

5. Izinyathelo Zokuphepha phakathi Nokulungiswa Kwe-PCB

Kubalulekile ukuthatha izinyathelo zokuvimbela ukugwema izingozi zokuphepha ngesikhathi sokulungisa.

● Izinto Ezisetshenziswayo Zokuzivikela: Lapho usebenza nezinga lokushisa eliphezulu noma amandla aphezulu, ukugqoka izinto zokuzivikela kuyadingeka.Izibuko zokuphepha kanye namagilavu kufanele kugqokwe ngesikhathi se-soldering kanye nezinqubo zokumba, ukuvikela ezingozini zamakhemikhali ezingaba khona.

Ukugqoka amagilavu ngenkathi ulungisa ama-PCB.

● I-Electrostatic Discharge (ESD): Ukuze uvimbele ukushaqeka kukagesi okubangelwa i-ESD, qiniseka ukuthi ukhipha umthombo wamandla futhi ukhiphe noma yimuphi ugesi osele.Ungakwazi futhi ukugqoka amabhande asesihlakaleni aphansi noma usebenzise omata be-anti-static ukuze uqhubeke unciphisa ubungozi be-ESD.

6. Uyilungisa kanjani i-PCB?

Amaphutha ajwayelekile ku-PCB ngokuvamile abandakanya ukukhubazeka kokulandela umkhondo, izingxenye, namaphedi e-solder.

6-1.Ukulungisa Imikhondo Elimele

Ukuze ulungise iminonjana ephukile noma eyonakele ku-PCB, sebenzisa into ecijile ukuze uveze indawo engaphezulu yomkhondo wangempela futhi ususe imaski ye-solder.Hlanza indawo yethusi nge-solvent ukuze ususe noma iyiphi imfucumfucu, usize ukufeza ukuqhubeka okungcono kagesi.

Kungenjalo, ungakwazi solder jumper izintambo ukulungisa iminonjana.Qinisekisa ukuthi i-diameter yocingo ifana nobubanzi bokulandelela ukuze kusetshenziswe kahle.

6-2.Ukushintsha Izingxenye Ezingalungile

Ukushintsha izingxenye ezilimele

Ukuze ususe izingxenye ezingalungile noma i-solder ngokweqile emalungeni e-solder, kuyadingeka ukuncibilikisa i-solder, kodwa kufanele kuqashelwe ukugwema ukukhiqiza ukucindezeleka okushisayo endaweni ezungezile.Ukulandela izinyathelo ezingezansi zokushintsha izingxenye kusekethe:

● Shisisa amalunga e-solder ngokushesha usebenzisa i-soldering iron noma ithuluzi lokuhlanganisa.

● Uma i-solder isincibilikisiwe, sebenzisa iphampu eqeda uketshezi.

● Ngemva kokukhipha konke ukuxhumana, ingxenye izohlukaniswa.

● Okulandelayo, hlanganisa ingxenye entsha bese uyidayisela endaweni.

● Sika ubude obudlulele bengxenye yomkhondo usebenzisa izisiki zezintambo.

● Qinisekisa ukuthi amatheminali axhunyiwe ngokuvumelana ne-polarity edingekayo.

6-3.Ukulungisa Iziphedi Ze-Solder Ezilimele

Ngokuhamba kwesikhathi, amaphedi e-solder ku-PCB angase aphakamise, agle, noma aphuke.Nazi izindlela zokulungisa amaphedi e-solder awonakele:

I-Lifted Solder Pads: Hlanza indawo nge-solvent usebenzisa i-swab yekotini.Ukuze ubophe iphedi ibuyele endaweni, sebenzisa i-conductive epoxy resin ku-solder pad bese uyicindezela phansi, uvumele i-epoxy resin ukuthi ilapheke ngaphambi kokuqhubeka nenqubo yokudayiswa.

Amaphedi eSoda awonakele noma Angcolisiwe: Susa noma usike i-solder pad eyonakele, uveze umkhondo oxhunyiwe ngokukhuhla imaski ye-solder ezungeze iphedi.Hlanza indawo nge-solvent usebenzisa i-cotton swab.Kuphedi ye-solder entsha (exhunywe kumkhondo), sebenzisa ungqimba lwe-epoxy resin esebenzayo futhi uyivikele endaweni.Okulandelayo, engeza i-epoxy resin phakathi kwe-trace ne-solder pad.Yilaphe ngaphambi kokuqhubeka nenqubo ye-soldering.

I-Shenzhen ANKE PCB Co., LTD

2023-7-20

Isikhathi sokuthumela: Jul-21-2023